4-Mar-2024

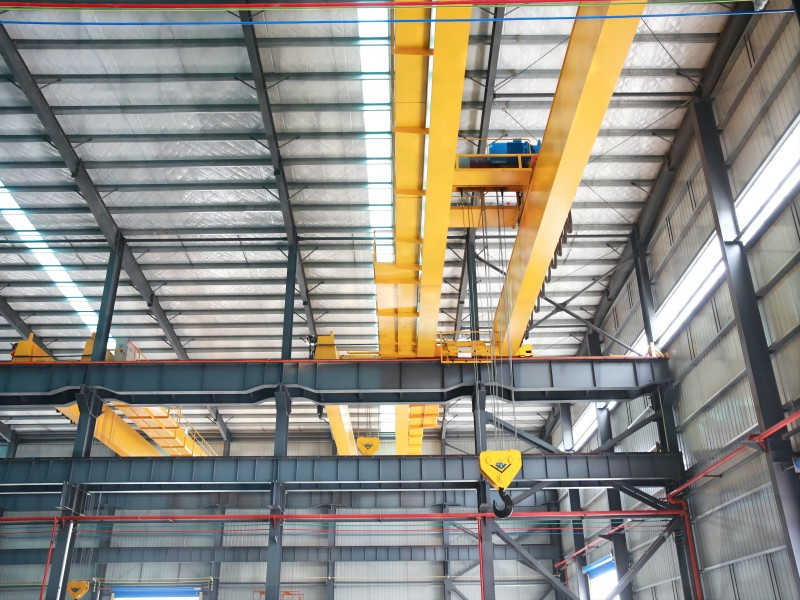

Dongqi Crane installs 10-ton double-girder overhead crane for China Heavy Industry Factory

This case is a Chinese heavy industry company purchasing a bridge crane from our factory. This enterprise is mainly engaged in the manufacturing, sales and maintenance of: excavating machinery, construction engineering machinery, plastic machinery and their corresponding spare parts and components; mechanical processing.

If you want to have an in-depth understanding of our factory strength, we have prepared detailed information for customers, including product technical specifications, performance data, usage effects, customer feedback, etc. You can also communicate with us to visit the factory directly and visit the site. At the site, you can personally demonstrate the functions and performance of the product, allowing customers to experience the advantages of the product for themselves.

QD type 10 ton double beam bridge crane parameters

1、 Basic parameters

- Rated lifting capacity: 20 tons

- Span: 22 meters (adjustable according to workshop size)

- Lifting height: 16 meters (adjustable according to process requirements)

- Work level: A6 (Heavy duty work system)

2、 Structural parameters

- Main beam type: Double beam box structure, with good bearing capacity and stability

- Main beam material: Q345B or higher strength low alloy structural steel

- End beam structure: box shaped structure, connecting the main beam and the crane operating mechanism

3、 Lifting mechanism parameters

- Lifting speed: dual or multiple speeds can be selected, for example: main lifting speed of 8 meters/minute, slow speed of 0.8 meters/minute

- Motor type: Metallurgical specific motor, with good heat and dust resistance performance

- Brake type: Normally closed electromagnetic brake, ensuring safe and reliable stopping of lifting movement

4、 Parameters of the crane operating mechanism

- Running speed of the large vehicle: for example, 40 meters per minute (adjustable according to actual needs)

- Motor type: Metallurgical specific motor, suitable for high temperature and dusty environments

- Wheel material and diameter: Cast steel wheels, surface hardening treatment to improve wear resistance; The diameter is determined based on the bearing capacity and wheel pressure

5、 Electrical system parameters

- Control voltage: usually 380V/50Hz, but can be adjusted according to local power grid standards

- Control system: PLC programmable control or relay logic control, realizing various actions and protection functions of the crane

- Protective devices: including overload protection, phase loss protection, short circuit protection, etc., to ensure the safe and reliable operation of the electrical system

6、 Safety facility parameters

- Buffer: Set buffers at both ends of the crane to absorb impact energy and protect the crane structure

- Windproof facilities: equipped with rail clamps, anchoring devices and other windproof equipment to ensure the stability of the crane in high wind speeds

- Limiting device: Limiting devices are installed for lifting, large and small vehicle operation to prevent safety accidents caused by over travel operation

- Emergency stop button: An emergency stop button is installed in the crane operation room and key locations to quickly cut off power and stop the crane operation in case of an emergency.