19-Mar-2025

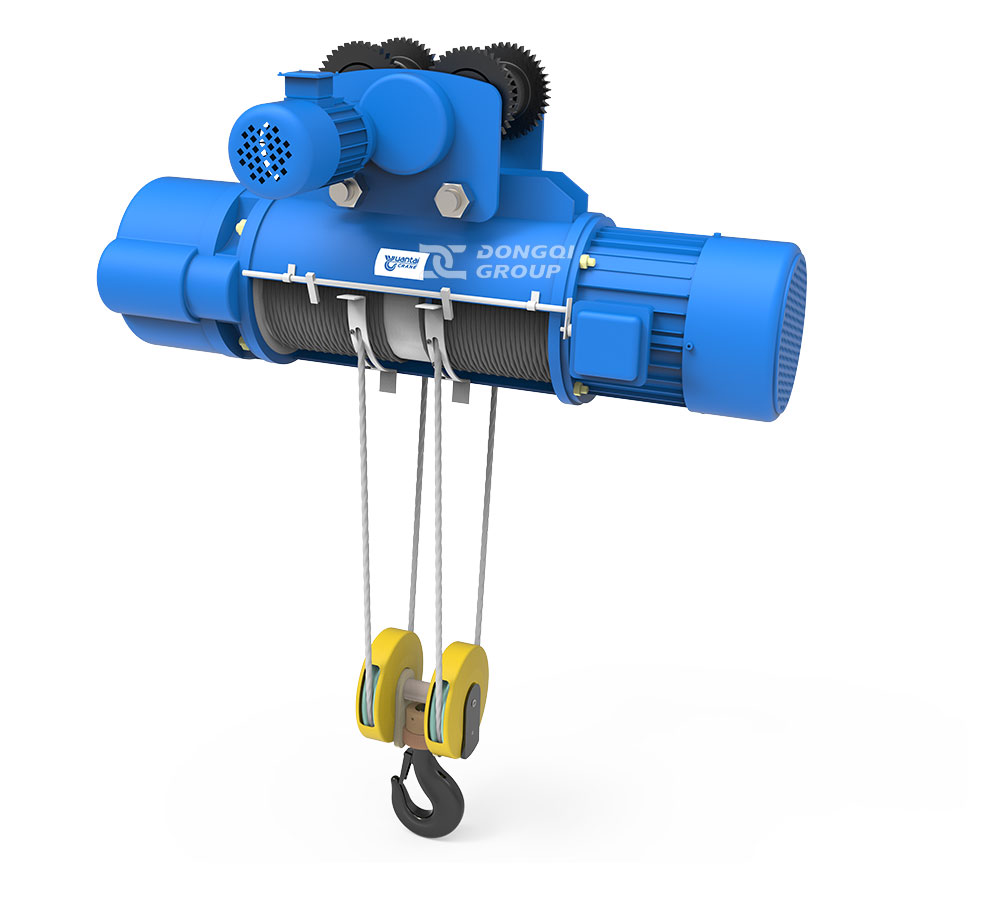

CD type wire rope electric hoist

As an efficient and reliable lifting equipment, CD type wire rope electric hoist plays a vital role in modern industry and construction. It has won wide recognition and application with its unique design concept and excellent performance. From precision machining workshops to busy construction sites, CD type wire rope electric hoist helps all kinds of heavy object handling operations to be completed smoothly with its powerful lifting capacity and stable operating performance. This manual aims to comprehensively introduce the product characteristics, structural composition, installation and commissioning, operating specifications and maintenance of CD type wire rope electric hoist, and provide users with detailed reference and guidance to ensure that the equipment can safely and efficiently serve various application scenarios.

Product Overview

Introduction to CD type wire rope electric hoist

CD type wire rope electric hoist is an efficient and reliable lifting equipment, widely used in various industrial sites. It has a compact design and is easy to operate. It is driven by an electric motor and uses wire rope to lift and lower heavy objects, realizing efficient material handling. This equipment not only has a strong lifting capacity, but also incorporates a number of safety protection measures to ensure the safety and stability of the operation process.

Main functions and features

The CD type wire rope electric hoist has many functions, such as precise control of the lifting speed of the load, overload protection device to prevent motor overheating, and convenient remote control operation options. Its characteristics are sturdy and durable structure, adaptable to various harsh working environments; at the same time, flexible operation, can meet the lifting needs of different heights and angles. In addition, the equipment is also equipped with a limit switch to ensure automatic stop when reaching the limit position to avoid collision damage.

Application field and scope

The CD type wire rope electric hoist is widely used in many fields such as manufacturing, logistics, and warehousing. In the production line, it can be used for material handling on the assembly line; in the logistics warehouse, it can help move goods quickly and accurately; in addition, on the construction site, the equipment is also an important tool for lifting construction materials. Its wide range of applications reflects its strong versatility and practicality.

Product advantages and selling points

The CD type wire rope electric hoist has won wide recognition in the market for its high efficiency, safety and stability. Its selling points are efficient lifting performance, convenient remote control operation, comprehensive safety protection measures and flexible application scenarios. These advantages make CD type wire rope electric hoist the preferred equipment for many companies to improve production efficiency and reduce labor intensity. In addition, the equipment also has excellent adaptability and customizability, which can meet the needs of different customers and special environmental requirements.

Product structure and technical parameters

Overall structural design

The overall structural design of the CD type wire rope electric hoist embodies the design concept of high efficiency, safety and reliability. The equipment is made of high-strength materials, such as high-quality alloy steel and stainless steel. These materials have excellent tensile strength and wear resistance, which can ensure that the hoist can maintain stable performance under long-term and high-intensity use, and have good corrosion resistance, especially suitable for harsh environments such as humidity and dust. Its compact structure is not only easy to install, but also reduces maintenance costs.

Key component description

The key components of the CD type wire rope electric hoist include motors, reducers, drums, wire ropes, and limit switches. The motor is used as a power source to provide a stable driving force. The reducer adopts high-precision gear transmission to effectively reduce the speed of the motor and increase the torque output to ensure that the load can be lifted and lowered smoothly. The drum is exquisitely designed to ensure that the wire rope remains stable during the winding process and avoid the phenomenon of tangled ropes. The wire rope is made of high-quality high-strength steel wire, which has sufficient strength and wear resistance to withstand various complex load conditions. The limit switch is installed at the lifting limit position of the equipment. Once the preset position is reached, it will be automatically triggered to stop the equipment from running, thereby effectively preventing equipment damage caused by overload or misoperation.

Technical Parameters Detailed Explanation

The technical parameters of CD type wire rope electric hoist are important indicators to measure its performance and scope of use. Lifting capacity is the maximum load weight that the hoist can safely lift; the working level indicates the operating efficiency and reliability of the hoist under different working conditions; the lifting speed and the lowering speed indicate the average speed of the hoist during the rising and falling processes respectively; the motor power determines the power output and operating efficiency of the hoist; the wire rope diameter directly affects the carrying capacity and service life of the hoist. Users can choose the appropriate model and specification according to actual needs and working environment.

Material and process standards

CD type wire rope electric hoist strictly follows relevant international and domestic standards such as ISO, DIN, etc. during the manufacturing process to ensure the accuracy and reliability of each component. The selection of high-quality materials such as high-strength alloy steel and stainless steel makes the hoist have good durability and corrosion resistance, and can maintain stable performance in various harsh environments. In addition, advanced process technologies such as welding and heat treatment are used in the manufacturing process to ensure the structural and performance stability of the equipment.

Installation and commissioning

Pre-installation preparation and inspection

Before installing the CD type wire rope electric hoist, the user must perform a series of preparations and equipment inspections. First, conduct a comprehensive assessment of the installation site to ensure that there is enough space to accommodate the running track of the hoist and the space required for the lifting operation. At the same time, confirm that the load-bearing structure on site can withstand the weight of the hoist and its load, especially for high-intensity and frequent use occasions. Be sure to verify that the bearing capacity of the building structure meets the equipment installation requirements.

Check whether the equipment itself and its accessories are intact, including but not limited to key components such as wire ropes, hooks, limiters, controllers, etc. If cracks, deformations, excessive wear or other functional abnormalities are found, they should be repaired or replaced in time to avoid safety hazards. Read and familiarize yourself with the instruction manual of the CD type wire rope electric hoist in detail, assemble and connect the equipment according to the instructions therein, and pay special attention to the matching accuracy and installation sequence between the components to ensure that all components are installed correctly.

During the installation process, use professional measuring tools to ensure the horizontality and verticality of the hoist body, which is an important step to ensure smooth operation of the equipment and reduce wear and failure. Horizontality refers to the stability of the hoist on the running track, and verticality refers to the vertical alignment of the hoist hook during the lifting process. Both need to be finely adjusted according to the requirements of the manual.

Installation steps and process

The installation steps include determining the installation location, fixing the hoist body, connecting the power supply and control lines, installing the remote control (if applicable), and performing preliminary debugging. Each step must be carried out according to the requirements in the manual to ensure the accuracy and safety of the installation process.

First, according to the actual situation on site and the operation requirements, select a suitable and stable installation location to ensure the stability and linearity of the hoist running track; according to the weight of the hoist and the working environment, reasonably plan and implement the basic fixing plan, generally use embedded parts or special brackets to stabilize the hoist body; according to the electrical wiring diagram, correctly connect the power cord and control line to the hoist control system, pay attention to ensure that all wiring is firm and reliable, and do a good job of waterproofing and dustproofing; if equipped with a remote control, refer to the manual to install the remote control, and perform necessary pairing and functional tests; after completing the above installation steps, start the equipment for preliminary debugging.

Debugging and trial operation guidance

After completing the installation of the CD type wire rope electric hoist, the user needs to debug and test the equipment. The debugging content includes checking the direction of the motor, the sensitivity of the limit switch, and the response speed of the remote control. The trial operation needs to be carried out under no-load and load conditions to verify the lifting performance and safety performance of the equipment.

During the debugging phase, carefully check whether the rotation direction of the motor meets the equipment operation requirements, whether the limit switch can be accurately triggered at the set position, whether the remote control operation is flexible and the response time meets the specifications; in the trial operation phase, first conduct a no-load test to confirm that the equipment is stable in the no-load state; then conduct a load test, gradually increase the load to the maximum rated value, and verify the lifting capacity and stability of the equipment under various working conditions; check whether all operating parameters meet the manufacturer’s specifications and relevant national standards, and confirm that all parts of the equipment are working normally and there is no abnormal sound or vibration.

Operation Guide

Start and stop operation

When starting the CD type wire rope electric hoist, the user should first ensure that the equipment is in a safe state, and then press the start button, and the equipment will start running. When it is necessary to stop, the user should quickly press the stop button to ensure the safety and stability of the equipment. During operation, the user should always pay attention to the operating status and load conditions of the equipment to ensure the safety and stability of the operation.

Load lifting and lowering control

The lifting and lowering of the load can be controlled by the buttons on the remote control or control panel. When lifting the load, the user should gradually accelerate to avoid a sudden rise in the load, which may cause overload or damage to the equipment. When lowering the load, the user should control the lowering speed to ensure that the load lands smoothly and avoid danger caused by excessive speed. At the same time, the user should also reasonably select the weight and size of the load according to the rated load range of the equipment to ensure that the equipment operates within the rated range.

Emergency Braking and Safe Operation

The CD type wire rope electric hoist is equipped with an emergency brake device to quickly stop the equipment in an emergency. The user should be familiar with the location and use of the emergency brake device so that it can be started immediately when necessary. In addition, during operation, the user should also comply with safety regulations, such as avoiding overloading and keeping the equipment clean. Users need to strictly abide by relevant safety regulations and operating procedures to ensure the safety of themselves and others. During operation, users should stay focused and alert, and pay attention to the operating status and surrounding environment of the equipment at any time. When it is necessary to stop the equipment, preparations should be made in advance to avoid danger caused by sudden braking.

Daily Maintenance and Maintenance Recommendations

To ensure the long-term and stable operation of the CD type wire rope electric hoist, users need to perform regular maintenance and maintenance. This includes checking the wear of the wire rope, cleaning the surface of the equipment, lubricating key components, and checking the connection of the electrical system. Users should also regularly check the lubrication of the equipment and replace the lubricating oil in time. During the inspection, if any abnormality is found in the equipment, it should be handled and maintained in time. At the same time, users should also record the operating data and fault conditions of the equipment so as to find and solve the problems in time. In addition, users should also operate and maintain the equipment in accordance with the operating instructions and maintenance requirements to ensure the normal operation and service life of the equipment.

Daily maintenance checklist (CD type wire rope electric hoist)

| Inspection items | Inspection content | Inspection frequency | Note |

| Wire rope | Wear condition, whether there is wire breakage or corrosion | Daily | Replace if necessary |

| Equipment Surface | Cleanliness, with or without oil and dust | Daily | Keep the equipment clean |

| Key components | Lubrication condition, whether there is abnormal wear and tear | Weekly | Timely replenishment of lubricating oil |

| Electrical system | Connection status, whether it is loose or damaged | Per month | Ensure reliable electrical connections |

| Brake device | Whether the function is normal and the response is fast | Per month | Ensure that the emergency brake is effective |

| Load capacity | Check according to the rated load range | Before each use | Avoid overloaded operation |

| Running records | Record equipment operation data and fault conditions | Daily | Easy to track and analyze problems |

| Lubricating oil | Lubricant quality, whether it needs to be changed | Quarterly | Use suitable lubricating oil |

Equipment maintenance and repair recommendation table

| Maintenance projects | Maintenance content | Maintenance Cycle | Precautions |

| Cleaning and maintenance | Clean oil and dust on the surface of the equipment | Daily | Use the right cleaning tools |

| Lubrication and maintenance | Lubricate key components and replace lubricating oil | Weekly/Quarterly | Use the lubricating oil recommended by the equipment manual |

| Electrical inspection | Check the connection of the electrical system | Every month | Ensure stable power connection and avoid electrical failures |

| Safety inspection | Check brake device, load capacity, etc. | Before each use/monthly | Ensure that equipment is operated in a safe condition |

| Maintenance records | Record maintenance time, content and results | After each repair | Easy to follow-up maintenance and troubleshooting |

| Storage management | Equipment storage environment, to avoid moisture, corrosion | Long | Ensure that equipment is stored in a dry, ventilated environment |

| Operational training | Provide safe operation training to operators | Regular | Improve operator safety awareness and operating skills |

Safety precautions

Operational safety specifications

When operating the CD type wire rope electric hoist, users must strictly abide by the following safety specifications: First, users must ensure that the equipment operates within the rated range and avoid overloading to avoid equipment damage or safety accidents. Secondly, users should keep the equipment clean and regularly clean the oil and debris on the surface of the equipment to maintain a good line of sight and operating environment. In addition, users should also regularly inspect and maintain the equipment to ensure its normal operation. When operating the equipment, users should be familiar with the operation methods of the equipment and master the skills of using the emergency brake device so that they can take quick measures in an emergency.

Use environment requirements

The use environment of the CD type wire rope electric hoist should meet the following requirements: First, the installation site should have sufficient space and load-bearing capacity to ensure that the equipment is installed stably and runs smoothly. Secondly, the environment should be kept dry and ventilated to avoid damage to the equipment caused by harsh conditions such as humidity and dust. In addition, users should also pay attention to the operating temperature range of the equipment and avoid using the equipment in high or low temperature environments.

Prohibitions and warnings

When operating the CD type wire rope electric hoist, users need to comply with the following prohibitions: First, it is forbidden to perform maintenance and care while the equipment is running to avoid accidental injuries. Secondly, it is forbidden to use the equipment with overload to avoid equipment damage or safety accidents. In addition, it is forbidden to place flammable and explosive items near the equipment to ensure the safety of the equipment. At the same time, the equipment is also equipped with warning signs and indicator lights to remind users to pay attention to safety in emergency situations.

CD type wire rope electric hoist troubleshooting and maintenance guide

Common fault phenomenon analysis

During the use of CD type wire rope electric hoist, various faults may be encountered. These fault phenomena are varied, such as the motor cannot start, the load cannot be lifted or lowered, and the remote control fails. These fault phenomena may be caused by a variety of reasons, including power failure, poor electrical connection, mechanical component damage, etc. In order to ensure the normal operation of the equipment, users must be familiar with these common fault phenomena and their possible causes so that they can be promptly checked and repaired when problems occur.

Troubleshooting steps and methods

When troubleshooting the CD type wire rope electric hoist, users need to follow certain steps and methods. First, the user needs to check whether the power supply and electrical connection are normal to ensure that the equipment can be powered normally. If the power supply and electrical connection are normal, the user needs to check whether the mechanical parts are damaged or worn, such as wire ropes, pulleys, bearings and other parts. If there is no problem with the mechanical parts, the user needs to check whether the control circuit and sensor are normal to ensure that the equipment can operate normally. When troubleshooting, the user also needs to use professional tools and equipment for detection and measurement to accurately determine the cause of the fault.

Guide to repair and replace parts

When repairing CD type wire rope electric hoist, users need to follow certain guidelines and principles. First, users need to use appropriate tools and materials for repair to ensure safety and reliability during the repair process. Secondly, users need to follow the correct repair steps and methods to ensure the normal operation of the equipment. Finally, users need to ensure that the repaired equipment meets safety standards and performance requirements to ensure the normal operation and use of the equipment. If the equipment has damaged or worn parts, users need to replace them in time to ensure the normal operation of the equipment. During the repair process, users also need to record the repair process and data for subsequent tracking and maintenance.

Safety precautions

Operational safety specifications

When operating the CD type wire rope electric hoist, users must strictly abide by the following safety specifications: First, users must ensure that the equipment operates within the rated range and avoid overloading to avoid equipment damage or safety accidents. Secondly, users should keep the equipment clean and regularly clean the oil and debris on the surface of the equipment to maintain a good line of sight and operating environment. In addition, users should also regularly inspect and maintain the equipment to ensure its normal operation. When operating the equipment, users should be familiar with the operation methods of the equipment and master the skills of using the emergency brake device so that they can take quick measures in an emergency.

Use environment requirements

The use environment of the CD type wire rope electric hoist should meet the following requirements: First, the installation site should have sufficient space and load-bearing capacity to ensure that the equipment is installed stably and runs smoothly. Secondly, the environment should be kept dry and ventilated to avoid damage to the equipment caused by harsh conditions such as humidity and dust. In addition, users should also pay attention to the operating temperature range of the equipment and avoid using the equipment in high or low temperature environments.

Prohibitions and warnings

When operating the CD type wire rope electric hoist, users need to comply with the following prohibitions: First, it is forbidden to perform maintenance and care while the equipment is running to avoid accidental injuries. Secondly, it is forbidden to use the equipment with overload to avoid equipment damage or safety accidents. In addition, it is forbidden to place flammable and explosive items near the equipment to ensure the safety of the equipment. At the same time, the equipment is also equipped with warning signs and indicator lights to remind users to pay attention to safety in emergency situations.

CD type wire rope electric hoist troubleshooting and maintenance guide

Common fault phenomenon analysis

During the use of CD type wire rope electric hoist, various faults may be encountered. These fault phenomena are varied, such as the motor cannot start, the load cannot be lifted or lowered, and the remote control fails. These fault phenomena may be caused by a variety of reasons, including power failure, poor electrical connection, mechanical component damage, etc. In order to ensure the normal operation of the equipment, users must be familiar with these common fault phenomena and their possible causes so that they can be promptly checked and repaired when problems occur.

Troubleshooting steps and methods

When troubleshooting the CD type wire rope electric hoist, users need to follow certain steps and methods. First, the user needs to check whether the power supply and electrical connection are normal to ensure that the equipment can be powered normally. If the power supply and electrical connection are normal, the user needs to check whether the mechanical parts are damaged or worn, such as wire ropes, pulleys, bearings and other parts. If there is no problem with the mechanical parts, the user needs to check whether the control circuit and sensor are normal to ensure that the equipment can operate normally. When troubleshooting, the user also needs to use professional tools and equipment for detection and measurement to accurately determine the cause of the fault.

Guide to repair and replace parts

When repairing CD type wire rope electric hoist, users need to follow certain guidelines and principles. First, users need to use appropriate tools and materials for repair to ensure safety and reliability during the repair process. Secondly, users need to follow the correct repair steps and methods to ensure the normal operation of the equipment. Finally, users need to ensure that the repaired equipment meets safety standards and performance requirements to ensure the normal operation and use of the equipment. If the equipment has damaged or worn parts, users need to replace them in time to ensure the normal operation of the equipment. During the repair process, users also need to record the repair process and data for subsequent tracking and maintenance.