21-Mar-2025

Installation Plan for Electric Single-Beam Cranes and Electric Hoists in Singapore

Introduction

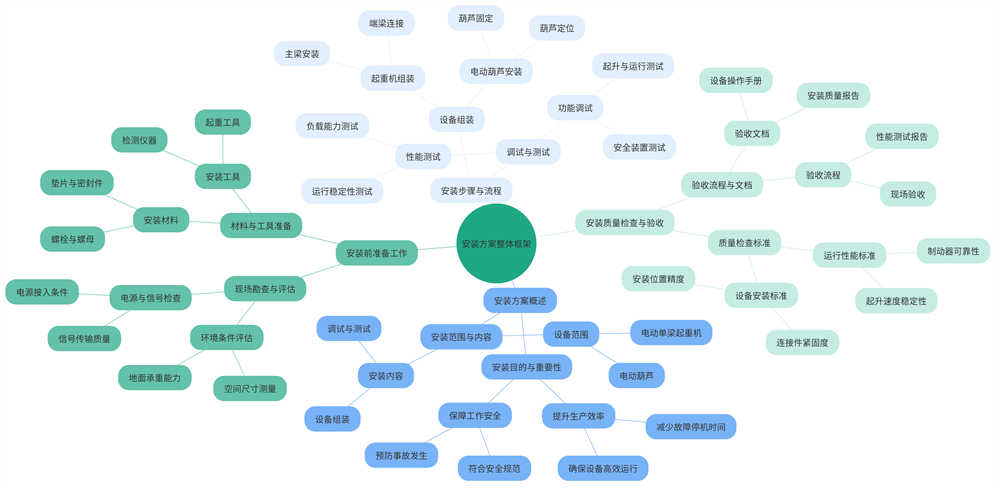

Electric single-beam cranes and electric hoists are essential lifting equipment in modern industrial operations. Their precise installation and efficient execution are critical to ensuring the safety and productivity of industrial processes. This installation plan provides a comprehensive and systematic guide for the installation of electric single-beam cranes and electric hoists in Singapore. It covers pre-installation preparation, detailed installation steps, and final quality inspection and acceptance. By adhering to scientific planning and rigorous execution, this plan ensures that the equipment operates stably and efficiently in various industrial settings. The plan emphasizes technical accuracy, safety management, and quality control, offering a reliable reference for installation teams.

Installation Plan Overview

Electric single-beam cranes and electric hoists are indispensable in Singapore’s industrial environment, where efficiency and safety are paramount. The quality of their installation directly impacts operational productivity and workplace safety. This installation plan outlines the step-by-step process for installing electric single-beam cranes and electric hoists, ensuring precision and reliability at every stage. The plan covers pre-installation preparation, installation procedures, and post-installation quality checks, providing a detailed manual for installation teams to follow.

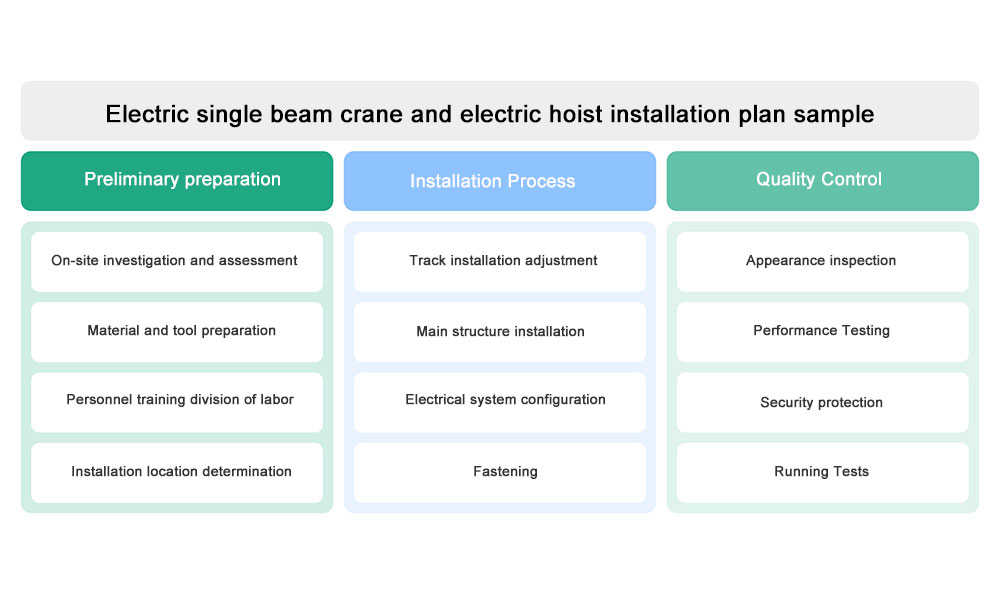

Installation Framework

1. Pre-Installation Preparation

1.1 Site Survey and Assessment

Before commencing installation, a thorough survey and assessment of the installation site are essential. This includes evaluating the factory structure, load-bearing capacity, spatial layout, and seismic performance to ensure the environment is safe and suitable for installation. Key considerations include:

- Structural Integrity: Verify the factory’s ability to support the crane and hoist loads.

- Safety Conditions: Assess ground flatness, obstacle clearance, and fire safety measures.

- Optimal Layout: Determine the best location for installation to maximize operational efficiency.

1.2 Preparation of Materials and Tools

All necessary materials and tools must be prepared in advance. This includes:

- Materials: Crane rails, structural components, electrical parts, etc., compliant with Singaporean standards.

- Tools: Lifting equipment, torque wrenches, electrical testing instruments, and safety gear.

1.3 Training and Division of Labor

Installation personnel must undergo comprehensive training on equipment structure, safety protocols, and emergency procedures. The team should be divided into specialized groups (e.g., hoisting, electrical, and safety teams) to ensure efficient and safe execution.

2. Installation Steps for Electric Single-Beam Cranes

2.1 Track Installation and Adjustment

- Preparation: Select and pre-process track materials according to design specifications.

- Installation: Use specialized tools to position and secure the tracks, ensuring straightness, horizontality, and verticality.

- Adjustment: Tighten bolts and perform pre-tightening checks to prevent deformation or loosening during operation.

2.2 Main Structure Assembly and Fixation

- Assembly: Follow design specifications to connect structural components securely.

- Fixation: Use high-strength bolts and welding to anchor the structure to the foundation, ensuring stability.

2.3 Electrical System Installation and Debugging

- Installation: Wire electrical components according to the system diagram.

- Debugging: Test control circuits, motor operation, and protection devices to ensure system reliability.

3. Installation Steps for Electric Hoists

3.1 Hoist Body Installation and Fixation

- Environment Check: Ensure the installation area is clean, flat, and free of obstructions.

- Lifting and Positioning: Use cranes or hoists to position the hoist body and secure it to the crane structure.

- Component Inspection: Check pulleys, wire ropes, and other parts for damage or wear.

3.2 Electrical Connection and Debugging

- Connection: Wire electrical components according to the system diagram, ensuring compliance with safety standards.

- Debugging: Test lifting, running, and braking functions to verify proper operation.

3.3 Safety Protection Device Installation and Verification

- Installation: Position limit switches, overload protection devices, and emergency stop buttons correctly.

- Verification: Test each safety device to ensure it functions effectively in emergencies.

4. Installation Quality Inspection and Acceptance

4.1 Appearance Inspection and Functional Testing

- Appearance Check: Inspect bolts, nuts, and surface coatings for damage or defects.

- Functional Testing: Test lifting, running, and braking functions under no-load and full-load conditions.

4.2 Safety and Reliability Evaluation

- Load-Bearing Capacity: Verify the equipment’s ability to handle long-term, high-intensity use.

- Stability: Assess operational stability and anti-tipping performance.

- Durability: Evaluate the fatigue resistance and lifespan of critical components.

4.3 Acceptance Report Preparation and Signing

- Report Preparation: Document the installation process, inspection results, and test outcomes.

- Review and Signing: Invite suppliers, third-party inspectors, and client representatives to review and approve the report.

Conclusion

This installation plan ensures the safe, efficient, and reliable installation of electric single-beam cranes and electric hoists in Singapore. By following this detailed guide, installation teams can achieve high-quality results that meet industrial standards and client expectations. The plan’s emphasis on safety, precision, and quality control guarantees that the equipment will deliver optimal performance in Singapore’s demanding industrial environment.

Appendices

- Site Survey Record Form

- Materials and Tools Checklist

- Installation Quality Acceptance Forms

- Safety and Reliability Evaluation Checklist

This plan serves as a comprehensive reference for installation teams, ensuring that electric single-beam cranes and electric hoists are installed to the highest standards in Singapore.

On-site investigation record form

| Exploration projects | Survey content | Survey results | Note |

| Factory Structure | Weight-carrying capacity | _ | Such as load-bearing capacity assessment report, etc. |

| Space layout | _ | Such as layout sketches or photos, etc. | |

| Seismic resistance | _ | Such as seismic test report, etc. | |

| Safety status | Ground flatness | _ | |

| Installation location | Recommended location | _ | |

| Other | _ | _ | Such as on-site special environment, potential hidden dangers, etc. |

Installation materials and tool preparation list

| Category | Material/Tool Name | Quantities | Note |

| Material | Crane tracks | _ | Comply with relevant national standards and design specifications |

| Tool | Lifting equipment | _ | Check and test before put into use |

| Other | _ | _ | Such as safety equipment, auxiliary tools, etc. |

Installation Quality Acceptance Form (Appearance Inspection)

| Inspection items | Inspection content | Inspection results (pass/fail) | Note |

| Connecting parts | Whether the bolts, nuts and other fasteners are firm and reliable, no loosening phenomenon | _ | |

| Paint coating | Whether the paint coating on the surface of the equipment is complete and undamaged, without scratch marks or rust phenomenon | _ | |

| Lifting function | No-load and full-load test hoisting, whether the lifting action is stable and accurate, and whether the limit switch is effective | _ | |

| Operating function | The crane is running back and forth on the track, whether it is walking smoothly, and whether there is any offset phenomenon. | _ | |

| Braking function | Repeatedly operate the lifting and running mechanism, whether it can stop accurately within the specified distance, and whether the emergency brake is effective. | _ |

Installation Quality Acceptance Form (Safety and Reliability Assessment)

| Evaluation projects | Evaluation content | Evaluation results (pass/fail) | Note |

| Load-bearing capacity | Is the bearing capacity of the equipment sufficient for long-term high-intensity use? | _ | |

| Stability | Stability during operation and anti-overturning ability under specific operating conditions | _ | |

| Durability | Anti-fatigue performance under long-term use, life of wearing parts, etc. | _ | |

| Acceptance Report | Record the equipment installation process, inspection results, functional test results, safety and reliability assessment conclusions | _ | See attachment for details |