20-Mar-2025

Crane Driving Assistant System

1. Introduction

In the rapid development of modern industrialization, cranes, as essential equipment for material handling, are widely used in various industrial scenarios. However, traditional cranes face numerous challenges during operation, such as blind spots in the driver’s perspective and reliance on manual driving experience. These issues not only affect operational efficiency but also pose potential safety risks. To address these problems, Dongqi Crane, leveraging its profound technical expertise and innovative spirit, has introduced the Crane Driving Assistant System. This system aims to enhance crane operation safety and driving experience through intelligent technology, driving the progress of industrial intelligence.

2. Existing Pain Points and Value Points

2.1 Existing Pain Points

- Blind Spots in Driver’s Perspective: Due to the limitations of the cab’s position, operators often struggle to fully grasp the surrounding environment, leading to blind spots and increasing the risk of collisions.

- Reliance on Manual Driving Experience: Crane operations heavily depend on the operator’s experience and judgment, which limits efficiency and makes it difficult to ensure optimal safety in every operation.

2.2 Value Points

- Integrated Positioning & Anti-Collision Functionality: The Dongqi Crane Driving Assistant System integrates positioning and anti-collision functions, enabling precise perception of crane position and real-time monitoring of collision risks, significantly improving operational safety.

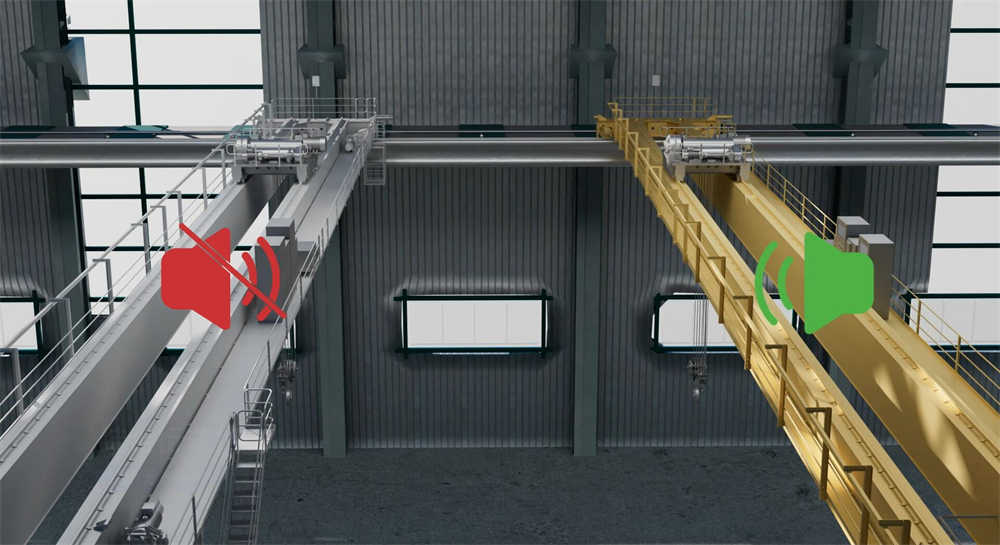

- Enhanced Safety and Driving Experience: Through intelligent technology, the system automatically adjusts crane speed to prevent collisions and provides clear visual and auditory warnings, allowing operators to work with greater confidence.

- Energy Efficiency and Environmental Protection: The system reduces unnecessary energy consumption and emissions, contributing to green development and lowering carbon footprints.

3. Product Advantages

The Dongqi Crane Driving Assistant System stands out among similar products due to its exceptional performance and advantages:

- IP67 Dustproof and Waterproof: The system’s hardware is designed to withstand harsh environments, ensuring stable operation.

- Vibration Resistance: The system maintains signal stability and accuracy even under significant vibrations during crane operation.

- Strong Anti-Interference Capability: Advanced anti-interference technology ensures reliable data transmission, unaffected by electromagnetic interference.

- Easy Installation and Short Debugging Cycle: The system’s hardware is designed for quick and simple installation, with support for remote debugging, significantly reducing setup time.

- Convenient Maintenance: The system features comprehensive fault diagnosis and alarm functions, enabling quick fault identification and reducing maintenance costs and downtime.

- Adaptability to Complex Scenarios and Industries: The system is highly flexible and scalable, suitable for various industries such as metallurgy, chemical, shipbuilding, mining, energy, and smart manufacturing.

4. Target Customer Positioning

4.1 Target Industries

The Dongqi Crane Driving Assistant System primarily targets industries with high demands for crane operation efficiency and safety, including metallurgy, chemical, shipbuilding, mining, energy, and smart manufacturing.

4.2 Application Scenarios

The system is particularly suitable for industrial scenarios with two or more cranes. In these scenarios, the need for collaborative operation and collision avoidance between cranes is particularly prominent, and the radar-assisted driving system can play the greatest role.

4.3 Compatible Crane Types

Dongqi Crane Driving Assistant System is applicable to various types of cranes, including but not limited to bridge cranes, gantry cranes, tower cranes, etc. As long as the crane has the hardware conditions required for installing the system (such as tracks, railings, etc.), the system can be deployed and applied.

4.4 Common Crane Parameters

In order to ensure the compatibility and applicability of the system, we need to understand some common parameters of the crane, such as the crane’s tonnage, span, height, operating speed, etc. These parameters will help us customize and optimize the system to ensure that the system can meet the actual needs of customers.

5. Product Details

5.1 System Components

The Dongqi Crane Driving Assistant System consists of four main components:

- Positioning base station: The positioning base station is installed on the end beams on both sides of the track to transmit and receive radio signals. By measuring the time difference of signal propagation, the location information of the vehicle can be accurately calculated to provide coordinate points for the system.

- Trolley tag: A trolley tag is installed on the trolley railing of each crane. The trolley tag receives the radio signal from the base station and reflects it back. By calculating the distance between the base station and the two tags, the location information and movement status of the vehicle can be obtained.

- Control unit: The control unit is installed on each crane and receives the location information and movement status provided by the trolley tag. According to the location information of the crane, the control unit can control the action of the relay, thereby realizing the deceleration and parking functions of the crane.

- Interactive panel: The interactive panel is installed in the cab of each crane to display the distance information between the current crane and the cranes or walls on both sides. When a danger is detected, the interactive panel will provide an integrated sound and light alarm prompt, allowing the driver to respond quickly.

5.2 System Functions

Dongqi Crane’s Driving Assistant System is divided into four areas: safety, warning, low speed, and danger according to the distance between the crane and obstacles, and provides corresponding functions according to different areas.

- Safe zone: When the crane is in the safe zone, the system does not make any prompts or actions, allowing the driver to focus on the operation process.

- Warning zone: When the crane enters the warning zone, if the system detects that the crane is traveling at high speed, it will prompt the driver to slow down to avoid potential collision risks.

- Low speed zone: When the crane enters the low speed zone, the system will first remind the driver and control the crane to slow down to 1st gear to ensure that it can maintain a safe speed when approaching obstacles.

- Danger zone: When the crane enters the danger zone, the system will immediately prompt the driver and control the crane to stop running to prevent collision accidents.

5.3 Optional Solutions

In order to meet the needs and scenarios of different customers, Dongqi Crane’s Driving Assistant System provides a variety of optional options.

- Planar Anti-Collision: Applicable to plane operation scenarios, it realizes the anti-collision function by measuring the horizontal distance between the crane and obstacles.

- Regional Anti-Collision: It is suitable for scenarios with specific working areas, and can realize real-time monitoring and anti-collision control of the crane position by setting multiple anti-collision areas.

- 3D Anti-Collision: It is suitable for working scenarios in three-dimensional space and realizes all-round anti-collision function by measuring the three-dimensional distance between the crane and obstacles.

5.4 Technical Features

Dongqi Crane’s Driving Assistant System has the following significant technical features:

- High Precision: The system uses advanced radio signal positioning technology with a positioning accuracy of up to 10cm, ensuring accurate perception of the crane’s position.

- Real-Time Monitoring: The system uses high-speed signal processing technology, which can complete data collection, processing and analysis in a very short time, ensuring real-time monitoring and rapid response to collision risks.

- Strong Stability: The hardware part of the system adopts a high reliability design and can operate stably in harsh environments, ensuring the long-term reliability and stability of the system.

6. Case Study

6.1 Case: An Aluminum Plant in Jiayuguan, Gansu, China

6.1.1 Customer Needs

There are 8 5t cranes distributed in two operation areas in the melting and casting operation area of an aluminum plant in Jiayuguan, and 46 32t cranes distributed in 6 independent cross-areas in the electrolytic aluminum operation area. Due to the large number of cranes, manual management and scheduling are required, which not only reduces the operation efficiency but also poses certain safety hazards and risks, and increases the probability of collision accidents between cranes and vehicles. Therefore, the aluminum plant urgently needs an intelligent crane anti-collision system to improve operation efficiency and safety.

6.1.2 Communication Process

In response to the needs of an aluminum plant in Jiayuguan, the Dongqi Crane team conducted in-depth communication and solution design. After understanding the complexity of the aluminum plant’s operating environment and the large number of vehicles, we decided to use a radar-assisted driving system to solve its anti-collision and positioning needs. During the solution design process, we fully considered the particularities of the aluminum plant’s operating environment, such as strong magnetic fields, high temperatures, dust, etc., and carried out targeted optimization and improvement of the system. After many discussions and modifications on the solution, we finally determined the anti-collision system solution that meets the actual needs of the aluminum plant.

6.1.3 Feedback

After the deployment and implementation of the system, the anti-collision system of an aluminum plant in Jiayuguan has been running stably for more than a year. During this period, the system has successfully avoided many potential collision accidents and greatly improved the efficiency and safety of operations. At the same time, the system also provides clear visual and auditory warning prompts, allowing drivers to be more calm and confident during operations. The aluminum plant is very satisfied with the use of the system and plans to install radar anti-collision products on other cranes. In addition, they also highly praised our after-sales service and technical support, and believed that our team performed well in solving problems and providing solutions.

7. Product Application Prospects and Outlook

With the advent of the Industrial 4.0 era, intelligence, automation and informatization have become important trends in industrial development. As an important innovative achievement in the field of material handling, the radar-assisted driving system of Dongqi Crane has broad application prospects and development space.

7.1 Application Prospects

- Metallurgical industry: In the metallurgical industries such as steel, aluminum, and carbon, cranes are indispensable material handling equipment. The application of radar-assisted driving systems will greatly improve the operating efficiency and safety of cranes and reduce the cost of manual management and scheduling.

- Chemical industry: In the chemical industry, due to the particularity and danger of the working environment, the demand for crane anti-collision and positioning is particularly prominent. The radar-assisted driving system can realize accurate perception of the crane position and real-time monitoring of collision risks, providing strong guarantee for the safe production of the chemical industry.

- Shipbuilding industry: Cranes play an important role in the construction and maintenance of ships. The application of radar-assisted driving systems will improve the efficiency and quality of ship construction and maintenance, while reducing potential safety risks.

- Mining industry: In the mining industry, due to the complexity and danger of the working environment, the safety and reliability of cranes are required to be high. The radar-assisted driving system can provide all-round anti-collision functions and accurate positioning information, providing strong support for the safe production of the mining industry.

- Energy industry: In the energy industry, such as nuclear power plants, hydropower stations and other places, the safety and stability of cranes are required to be extremely high. The application of radar assisted driving system will improve the operation of cranes in these places.

7.2 Future Outlook

With the continuous advancement of technology and the continuous expansion of application scenarios, the application prospects of Dongqi Crane’s Driving Assistant System will be broader and deeper.

- Integration of intelligent manufacturing and industrial Internet: In the future, radar-assisted driving systems will be more closely integrated with intelligent manufacturing and industrial Internet technologies. Through the Internet of Things (IoT) technology, cranes can upload operating data to the cloud in real time to achieve remote monitoring, data analysis and intelligent scheduling. This will further improve the operating efficiency of cranes, optimize production processes, and provide data support for corporate decision-making.

- Automation and unmanned trends: With the increasing maturity of automation technology, radar-assisted driving systems will become one of the key technologies to promote the automation and unmanned process of cranes. Through the integration of technologies such as automatic navigation systems and machine vision, cranes can achieve fully autonomous operation, reduce human intervention, and improve operation safety and continuity.

- Intelligent maintenance and predictive maintenance: With the help of big data analysis and artificial intelligence technology, radar-assisted driving systems can monitor the operating status of cranes in real time, predict potential failure risks, and perform maintenance in advance. This will greatly reduce the failure rate of cranes, extend their service life, and reduce maintenance costs.

- Cross-industry application expansion: In addition to traditional industries such as metallurgy, chemical industry, shipbuilding, mining, and energy, radar-assisted driving systems will gradually expand to more fields, such as construction, logistics, and warehousing. These industries have an increasing demand for cranes, and their requirements for operating efficiency and safety are also getting higher and higher. The application of radar-assisted driving systems will help these industries achieve intelligent upgrades and enhance overall competitiveness.

- Standardization and international development: With the continuous maturity of product technology and the continuous growth of market demand, Dongqi Crane’s radar-assisted driving system will actively promote standardization and international development. By aligning with international standards and participating in international market competition, Dongqi Crane will continue to enhance the international influence and competitiveness of its products and provide global customers with better intelligent solutions.

- Continuous technological innovation and upgrading: In the face of ever-changing market demands and increasingly fierce market competition, Dongqi Crane will always maintain an innovative spirit and continue to innovate and upgrade its radar-assisted driving system. By introducing new technologies, new algorithms, and new materials, we will continuously improve the performance and functions of our products to meet the diverse needs of our customers.

Component Selection

Equipment Wiring

In conclusion, the Dongqi Crane Driving Assistant System represents a groundbreaking advancement in crane operation safety and efficiency. By addressing critical challenges such as blind spots and reliance on manual expertise, the system not only enhances operational safety but also drives productivity and sustainability. Its adaptability to complex environments, combined with advanced features like high-precision positioning and real-time monitoring, makes it an indispensable tool across industries such as metallurgy, chemical, shipbuilding, mining, and energy.

Looking ahead, the system is poised to play a pivotal role in the era of smart manufacturing and industrial automation. Its integration with IoT, predictive maintenance, and Unmanned Driving Solutions for Cranes will further revolutionize material handling, paving the way for fully autonomous and intelligent crane operations. Dongqi Crane remains committed to innovation, continuously refining its technology to meet the evolving needs of global industries. With the Crane Driving Assistant System, Dongqi Crane is not just solving today’s challenges but also shaping the future of industrial intelligence, ensuring safer, smarter, and more sustainable operations worldwide.