31-Oct-2023

Overhead Crane With Grab Singapore

We provide various types of cranes in Singapore according to customer needs, including grab cranes. Grab type crane is a type of overhead crane, generally used for loading various bulk cargo, logs, ores, coal, sand and gravel, earthwork, etc. in ports, docks, station yards, mines, etc. The grab type overhead crane is also suitable for loading, unloading, handling, and transportation of pallets in power plants, freight stations, production workshops, and other places. These characteristics make the grab crane an important loading and unloading tool, greatly improving loading and unloading efficiency and production safety.

Our grab overhead cranes for garbage are designed and manufactured in accordance with GB, FEM IEC and other national and international standards. The structure is available in single-, double-, single and double-reel sets.Integrated weighing accuracy ≤ ±1%. Three modes of control: manual, semi-automatic and fully automatic. The three modes are freely switchable and have a manual priority function in any of the automatic modes. At present our products are widely used in waste incineration plants with a capacity of 4800t/d,3000t/d, 2400t/d, 1200t/d, 1000t/d, 800t/d and less than 600t/d.

QZ Overhead Crane With Grab

Supply Scope

Our company mainly produce grab overhead crane series with lifting capacity of 5-20t, lifting height of 1-30m, and A6 of medium working duty, also can designe and manufacture non-standard series hoist according to your demands.

Applications

- Widely used for loading and unloading and transferring of bulk materials in Power plants, garages, workshops, docks, etc.

- The rated capacity including the grab’s weight.

- Banned to use in flammable, explosive, corrosive media environment.

Grab cranes are mainly used in the following fields in Uzbekistan:

- Construction industry: Uzbekistan’s construction industry is developing rapidly, involving numerous construction projects, including residential, commercial and industrial construction, highway and railway construction, etc. The grab crane is one of the indispensable mechanical equipment in the construction industry, used for lifting and transporting various building materials such as cement, sand, steel bars, etc. on construction sites.

- Mining and Metallurgical Industry: Uzbekistan’s mining and metallurgical industry is relatively developed, involving the mining and processing of copper, gold, zinc, iron and other mineral deposits. The grab crane is used for lifting and transporting ores, waste rocks, and semi-finished materials in these mines, and is one of the important lifting equipment in the mining and metallurgical industries.

- Agriculture: Uzbekistan is one of the largest agricultural countries in Central Asia, with a wide agricultural planting area, including crops such as cotton, wheat, and corn. The grab crane is one of the indispensable mechanical equipment in the agricultural field, used for lifting and transporting crops in these fields.

- Transportation sector: Uzbekistan’s transportation industry is relatively developed, including railway, road, air, and waterway transportation modes. Grab crane is one of the important lifting equipment in the field of transportation, used for lifting and transporting various goods in transportation places such as railway stations, airports, and docks.

- Petrochemical industry: Uzbekistan’s petrochemical industry is developing rapidly, involving the processing and storage of energy products such as oil and natural gas. The grab crane is used to lift and transport various chemical raw materials, intermediate products, and finished products in these places, and is one of the important lifting equipment in the petrochemical industry.

Applicable Scope & Working Conditions

This crane is used in ambient temperature of -25℃~+40℃,humidity≤85%,elevation is under 1000m,power supply is 3-ph, 380V,50HZ (can change as user demand).

Main Structure and Characters

Mainly composed by 5 parts: bridge, trolley and crane traveling mechanism, electric equipment, grab, and other accessories.

Bridge

- Double girder, welding box beam, national standard camber;

- Q235 or Q345 steel material(same as Fe37 or Fe52 steel in abroad);

- The main weld adopt automatic submerged arc welding, NDT;

- End carriages connecting by high strength bolts and nuts, convenient in transportation;

- With the uniform, fine, bright, complete and consistent painting color;

- With painting thickness of 25~35μm each layer and whole thickness of 75~105μm.

Trolley

- Lifting mechanism is composed by motor, brake, coupling, transmission shaft, reducer, pulley blocks, wire rope, and other accessories;

- Crane dedicated YZR type wound motor, insulation class F;

- Closed Hydraulic push rod type brakes, which closed when machine not working, and opened by brake releases device when working;

- Roll casting reel, wire rope angle <3.5 ° , with 3 laps and 2 laps fixed circle at both ends of reel;

- Crane dedicated 6W(19) wire rope, line contact type, high strength, long life;

- Rotating limit switch set on spindle nose of the winding drum to keep the safe lifting;

- Specific Organization Chart

Crane traveling mechanism

- There are four traveling wheels installed on each side of the two end beams. Two of them are active wheels and the others are driven ones. The driving device of active wheels is installed on the walkway. Here adopt two sets of symmetrical independent driving devices and we call it respectively driven.

- The reducer adopts circular-arc gear one of which load capacity is higher than involute gear reducer of the same type. All of the mechanisms adopt rolling bearing with A.C. electromagnetic block brake.

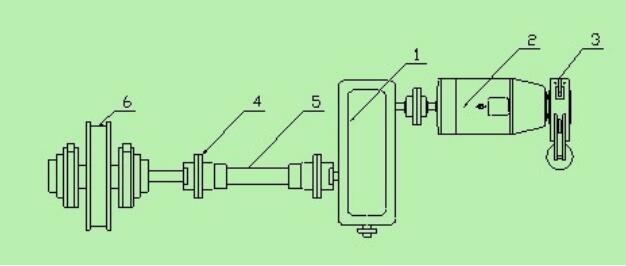

- Driving devices include 1. Reducer; 2. Motor; 3. Brake; 4. Coupling; 5.Coupling; 6. Wheels, etc are shown in the mechanical drawing as follows:

- The connection of the mechanism parts all adopt gear coupling. In this way, it can work well by gear coupling compensated even there is an error caused in manufacture and installation or deflection between the parts caused by bridge deformation when loading

- Active and driven wheel axle support on the angular bearing box for easy assembly and maintenance.

Electric equipment

- Electric control box layout is reasonable, easy to repair

- Security trolley line or angle steel trolley line

- External cable are equipped with mark line number

- Trolley moving’s power is supplied by flat cable

- The conductor is I steel or C shape sliding line

- Safety sliding touch line with high conductive rate and low pressure drop; current collector with high speed.

- Lifting and crane can be independently controlled; also can work separately or together.

Grabs

- Four-rope grab、double-rope grab

- Orange-petal grab、electric & hydraulic grabs

- Straw grab, wood grab, and other rich series varieties

Grab Crane Operating Principle

- Grab is the lifting appliance using jaws open and close to load or unload the bulk materials.

- According to the operating feature, grab can be divided into 3 kinds, double-rope, single-rope, and motor grab. The most commonly used is double-rope grab.

- According to the packing density of the materials, grab can be divided into light (such as to crawl grain), medium (such as to crawl gravel) and heavy (such as to grab iron ore)

- According to the jaw plate number, it can be divided into dual jaw plate grab and multitude jaw plate grab, the most commonly used is dual jaw plate grab

- Customers should adopt the multitude jaw plate grab to crawl the lump ores, scrap iron and scrap, because with the characteristics of more claws and notch tip, it can easily insert the stockpile and do a good crawl.

- The crane choose the dual winding drums four rope grab as its crawl device, structure simple and reliable.

- Mainly consisted of four parts: 1.head 2. Lifting beams 3.pull bar 4. bucket

- Trolley equipped with lifting winding drum and opening and closing winding drum, each set of rolls leads to two wire rope, including two as a group in both ends of grab balance frame for support, and another set of wire rope going through the upper beam pulley and under beam pulley to form a pulley set, making bucket Ministry open and close.

- When start working, grab lifting suitable position by support wire rope, then put down close wire rope, dead weight below lifting beam compel in the center of lifting beam below grab open the grab, when the two auricular plate collision, it is the max limite opened. When open grab, the center distance increased between up lifting beam pulley and down lifting beam, then drop the support wire rope, make the opened grab fall on the slack stack, and then furl close wire rope, make the center distance between up lifting beam pulley and down lifting beam pulley resume primary position, the course of snatch material has been finished. The closed grab fill full of material, at last lifting the close wire rope, whole grab is lifted, static crane be removed need yard, open grab unload the snatch material.

- Customers should highlight the require when crawling underwater materials or special materials and when using outside you should set rainproof devices.