23-Apr-2025

1 ton electric chain hoist

Introduction to Dongqi’s 1 Ton Electric Chain Hoist

A 1 ton electric chain hoist is a versatile and efficient lifting device designed for material handling in various industries, including manufacturing, construction, warehousing, and logistics. Dongqi Crane offers high-quality electric chain hoists that ensure safety, durability, and precision in lifting operations.

Our 1 ton electric hoist is ideal for applications requiring smooth and controlled lifting of heavy loads. With options like low headroom, fixed, and trolley-mounted configurations, these hoists provide flexibility for different workspace requirements.

Product Specifications & Key Features

- Capacity: 1 ton (1000kg) standard lifting capacity

- Lift Speed: 8/2 m/min (dual speed optional)

- Power Supply: Available in 110V, 220V and 380V models

- Chain: Grade 80 alloy steel, heat-treated for durability

- Protection Class: IP54 standard (IP55 optional)

- Duty Cycle: 30% ED (upgradeable to 40% ED)

Safety Features Include:

✓ Dual braking system (mechanical + electromagnetic)

✓ Overload protection device

✓ Upper/lower limit switches

✓ Emergency stop button

Three Main Configurations of 1 Ton Electric Chain Hoist

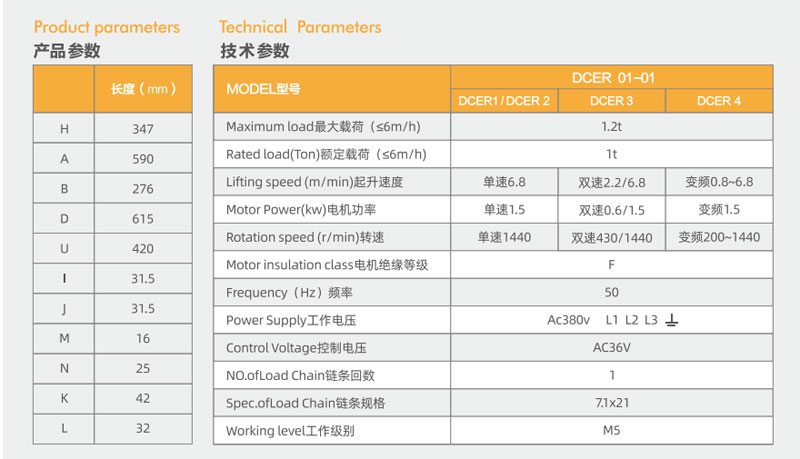

1. Low Headroom Electric Chain Hoist (Space-Saving Solution)

Best for: Facilities with limited vertical clearance

Technical Specifications:

- Minimum headroom requirement: 580-650mm (model dependent)

- Lift height: Up to 30m standard (custom heights available)

- Chain falls: Single or double (for improved stability)

- Motor power: 1.5kW (standard 380V model)

Key Advantages:

✓ 25% more lifting space than conventional hoists

✓ Precision dual-speed control (8/2 m/min)

✓ Integrated overload protection system

✓ Corrosion-resistant coating for harsh environments

Typical Applications:

- Automotive assembly lines

- Low-ceiling maintenance workshops

- Compact production cells

- Underground parking garage repairs

2. Fixed Mounting Electric Chain Hoist (Economical Workhorse)

Best for: Permanent lifting stations

Technical Specifications:

- Mounting options: Top plate, clevis, or lug

- Standard lift speed: 8 m/min (variable speed optional)

- Control: Pendant (10m cable) or wireless remote

- Ambient temperature range: -20°C to +60°C

Key Advantages:

✓ Lowest total cost of ownership

✓ Simplified maintenance (only 3 lubrication points)

✓ 30% duty cycle standard (upgradeable to 40%)

✓ IP55 protection available for damp environments

Typical Applications:

- CNC machine loading/unloading

- Fixed-position material handling

- Production line workstations

- Foundry and forging operations

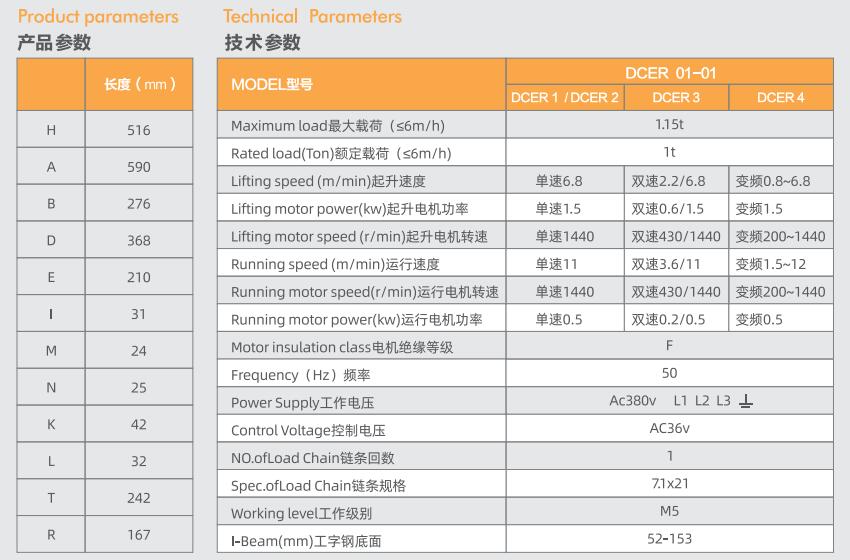

3. Electric Chain Hoist with Trolley (Maximum Flexibility)

Best for: Applications requiring horizontal movement

Trolley Options:

| Type | Speed | Load Capacity | Control |

|---|---|---|---|

| Manual Push | N/A | 1 ton | Hand chain |

| Geared Trolley | 0.8 m/s | 1 ton | Hand chain |

| Motorized Trolley | 20 m/min | 1 ton | Electric |

System Features:

- Beam width adaptability: 100-400mm

- Optional variable frequency drive for trolley

- Anti-sway control available

- Can be integrated with monorail systems

Key Advantages:

✓ Increases work area coverage by 300%

✓ Reduces manual labor by 60%

✓ Can be automated for smart factories

✓ Compatible with most standard I-beams

Upgrade Options:

- Explosion-proof version (ATEX certified)

- Stainless steel construction for food industry

- Cold storage package (-40°C operation)

- Smart control with IoT connectivity

Technical Comparison Table:

| Feature | Low Headroom | Fixed Mount | Trolley System |

|---|---|---|---|

| Price Range | $$$ | $ | $$-$$$ |

| Installation Time | 2 hours | 1 hour | 3-4 hours |

| Maintenance Interval | 500 hours | 800 hours | 300 hours |

| Lifespan | 10+ years | 12+ years | 8-10 years |

| Best For | Space constraints | Budget projects | Flexible handling |

Expert Recommendation:

For most industrial applications, we recommend the motorized trolley system as it provides the best balance of flexibility and productivity. However, for operations with:

- Very limited budgets → Choose fixed mount

- Extreme height restrictions → Select low headroom

- Infrequent movement needs → Manual trolley

Custom Solutions Available:

All configurations can be customized with:

- Special voltage requirements (440V, 575V, etc.)

- Hazardous location certifications

- Custom lift speeds

- Special hook designs (rotating, C-hook, etc.)

All prices FOB Shanghai, lead time 2-4 weeks

Dongqi Crane 1 Ton Electric Chain Hoist Price List

(All prices FOB Shanghai, USD)

1. Basic Fixed Mount Hoist

| Lift Height | Speed | Voltage | Price Range |

|---|---|---|---|

| 3m | 8m/min | 220V/380V | $450-$550 |

| 6m | 8m/min | 220V/380V | $500-$600 |

| 9m | 8/2m/min | 220V/380V | $580-$680 |

| 12m | 8/2m/min | 110V | $650-$750 |

Options:

- +$80 for variable speed control

- +$120 for IP55 protection

- +$150 for explosion-proof version

2. Low Headroom Hoist

| Lift Height | Headroom | Price Range |

|---|---|---|

| 3m | 600mm | $680-$780 |

| 6m | 620mm | $750-$850 |

| 9m | 650mm | $850-$950 |

| 12m | 650mm | $950-$1,100 |

Features Included:

- Dual speed as standard

- Overload protection

- CE certification

3. Trolley Systems

| Type | Beam Width | Price Range |

|---|---|---|

| Manual Push | 100-300mm | $150-$250 |

| Geared Trolley | 150-400mm | $300-$400 |

| Motorized Trolley | 200-500mm | $800-$1,200 |

Complete Packages:

- Fixed + Manual Trolley: $600-$800

- Low Headroom + Geared Trolley: $1,000-$1,300

- Standard + Motorized Trolley: $1,400-$1,800

Price Factors Breakdown

- Lift Height:

- +$50 per additional 3m beyond 12m

- Voltage:

- 110V models cost 15% more than 380V

- Speed:

- Dual speed adds 10-15%

- Certifications:

- CE: +$80 / GOST: +$150 / ATEX: +$300

Special Offers

- Bulk Discounts:

- 5-9 units: 5% off

- 10+ units: 8-12% off

- Accessories:

- Remote control: +$120

- Radio control: +$250

- Load limiter: +$180

Delivery & Warranty

- Lead Time: 15-30 days

- Warranty: 18 months standard

- MOQ: 1 unit (custom orders 3+ units)

Note: Final pricing depends on exact specifications. Contact our sales team for project-specific quotations with 24-hour response guarantee.

Would you like me to prepare a customized quote based on your specific requirements? We can provide exact pricing for your:

✓ Desired configuration

✓ Required certifications

✓ Quantity needed

✓ Destination port

Why Choose Dongqi Crane?

✔ 18 years of hoist manufacturing experience

✔ CE, ISO, and GOST certified

✔ 12-month warranty standard

✔ 24/7 technical support

✔ Custom solutions available

Frequently Asked Questions

1. What is the maximum lifting height for a 1-ton electric chain hoist?

- Standard models typically offer 3m to 12m lift height.

- Custom solutions can extend up to 30m with reinforced chain and motor upgrades.

- Low headroom models optimize vertical space but may have slightly reduced max height.

2. Can I use a 110V hoist in industrial settings?

- Yes, our 1 ton electric chain hoist 110V is designed for:

✓ Workshops with limited power supply

✓ Construction sites using generators

✓ Light industrial applications - Note: 110V models have slightly lower speed than 220V/380V versions.

3. What’s the difference between manual and motorized trolleys?

| Feature | Manual Trolley | Motorized Trolley |

|---|---|---|

| Cost | $150-$250 | $800-$1,200 |

| Operation | Hand-pushed | Electric drive (20m/min) |

| Best For | Occasional movement | Frequent/material handling |

Pro Tip: Geared trolleys ($300-$400) offer a middle-ground solution.

4. How often does the chain need lubrication?

- Self-lubricating chains: Every 500 operating hours

- Standard chains: Every 200-300 hours

- Harsh environments: Monthly inspections recommended

5. What safety features are included?

All Dongqi hoists come with:

✓ Dual braking system

✓ Upper/lower limit switches

✓ Overload protection (automatic cutoff at 110% capacity)

✓ Emergency stop button

6. Can I upgrade an existing hoist with a trolley?

- Yes, if the hoist has:

- Compatible mounting points

- Sufficient motor capacity

- Cost: $200-$600 depending on trolley type

- Lead Time: 1-2 weeks for retrofit kits

7. What’s the lifespan of a 1-ton electric hoist?

- Standard Use: 8-10 years (1,500+ cycles/year)

- Heavy Duty: 5-7 years (3,000+ cycles/year)

- Key Factors: Proper maintenance, load frequency, environment

8. How do I choose between fixed and trolley-mounted?

- Fixed Mount if:

- Lifting in one permanent location

- Budget under $600

- Trolley System if:

- Horizontal movement needed

- Working with I-beams or monorails

9. Are explosion-proof models available?

Yes, ATEX-certified hoists feature:

- Spark-proof construction

- Enhanced thermal protection

- 20-30% higher price than standard models

10. What’s included in the warranty?

- 12 months for mechanical/electrical parts

- Exclusions: Wear items (chains, brakes), misuse damages

- Extensions: Available for +2 years at 8% of product cost

Need More Answers? Contact our engineers at [sales010@cranesdq.com/+86 18638815424] for technical support within 4 business hours.