21-Apr-2025

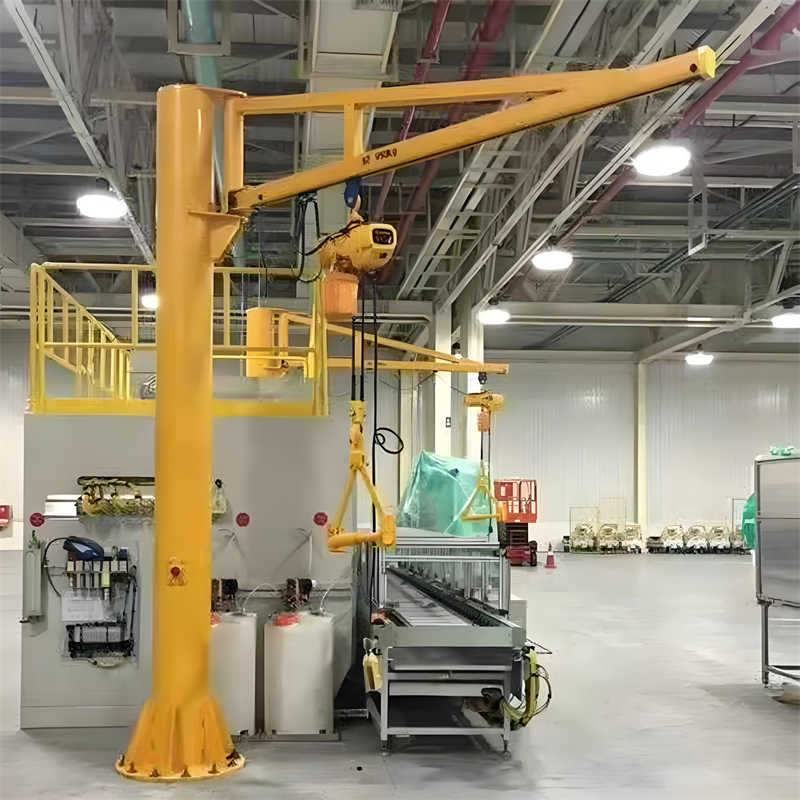

3 Ton Jib Crane

Introduction

Dongqi Crane presents its premium 3 Ton Jib Crane series – engineered for precision lifting in industrial environments. Whether you need fixed-position stability or mobile flexibility, our pillar-mounted and mobile jib cranes deliver exceptional performance with 3-ton capacity, 360° rotation, and space-saving designs.

Why Choose Dongqi 3 Ton Jib Crane?

✅ Superior Load Handling – Precisely engineered for 3-ton (3,000kg) lifting with safety margins exceeding industry standards.

✅ Dual Configuration Options:

- Pillar-Mounted Jib Cranes: Ideal for permanent workstations

- Mobile Jib Cranes: Perfect for multi-location material transfer

✅ Smart Control Systems:

- Standard manual operation

- Optional radio remote control (up to 100m range)

- Variable frequency drives for smooth acceleration

✅ Durability Guaranteed:

- Structural steel: Q345B (high tensile strength)

- Surface treatment: Sandblasting + epoxy coating (80μm)

- IP54 protection (standard) / IP65 (optional)

Technical Specifications

| Model | DQ-PJ3 (Pillar) | DQ-MJ3 (Mobile) |

|---|---|---|

| Capacity | 3 ton | 3 ton |

| Boom Length | 3-8m | 2.5-6m |

| Rotation | 360° manual/motorized | 360° manual + optional motorized |

| Lifting Speed | 8/4 m/min (dual-speed hoist) | 5-10 m/min (adjustable) |

| Power Supply | 380V/50Hz/3-phase | Battery/380V options |

| Duty Class | FEM 1Am (ISO A3) | FEM 1Am (ISO A3) |

Industry-Specific Solutions: Where Our 3 Ton Jib Crane Excels

1. Manufacturing & Assembly Operations

Precision Component Handling:

- Engine block positioning in automotive plants (±2mm accuracy)

- Mold changes for injection molding machines (quick-connect tooling)

- Press feeding operations with controlled descent

Workstation Solutions:

- Ergonomic parts transfer between assembly stations

- Just-in-time component delivery to production lines

- Heavy fixture handling for welding cells

2. Warehouse & Logistics Centers

Loading Dock Applications:

- Container unloading (compatible with ISO container dimensions)

- Palletized goods transfer (integrated with pallet jacks)

- Cross-docking operations between trucks

Specialized Handling:

- Drum rotation for filling stations (optional rotating attachments)

- Coil handling in steel service centers (C-hook compatible)

- Bagged material positioning (dust-proof versions available)

3. Maintenance & Repair Facilities

Equipment Servicing:

- Turbine maintenance in power plants (explosion-proof options)

- Locomotive engine removal (low-clearance designs)

- Hydraulic press ram extraction (precise load control)

Aircraft Hangar Applications:

- Engine changes (clean room configurations)

- Landing gear servicing (certified aviation jib designs)

- Composite wing handling (anti-static models)

4. Construction & Infrastructure Projects

Job Site Versatility:

- Precast concrete panel placement (outdoor-rated models)

- Mechanical room equipment installation (compact designs)

- Bridge bearing replacement (high-precision models)

Temporary Installations:

- Modular building assembly (quick-deployment systems)

- Temporary maintenance platforms (integrated with scaffolding)

- Disaster recovery operations (rapid-response configurations)

5. Marine & Offshore Applications

Dockyard Solutions:

- Ship component handling (saltwater-resistant models)

- Propeller shaft servicing (high-moment capacity)

- Deck equipment maintenance (motion-compensated versions)

Special Environments:

- Below-deck operations (low-profile designs)

- Floating dock applications (wave-motion adapted)

- Ice-class configurations for Arctic operations

6. Energy Sector Applications

Power Generation:

- Transformer handling in substations (insulated versions)

- Wind turbine component service (field-repairable designs)

- Solar panel array installation (extended reach models)

Oil & Gas:

- Christmas tree handling (ATEX certified)

- Pipeline valve maintenance (corrosion-resistant)

- Refinery vessel internals (spark-proof configurations)

Each application-specific package includes:

- Custom boom length calculations

- Site-specific load diagrams

- Interface engineering for existing systems

- Safety system integration (anti-collision, overload protection)

Technical Support: Our engineers provide application validation services including FEA analysis of your specific lifting scenarios to ensure optimal performance and safety.

3 Ton Jib Crane Price – Complete Cost Breakdown & Buying Guide (2024)

When investing in material handling equipment, understanding 3 ton jib crane price factors is crucial for budget planning. This comprehensive guide examines all cost components to help you make an informed purchase decision.

1. Base Price Range (2024 Market Data)

- Pillar-mounted models: $5,800-$12,500

- Mobile versions: $8,500-$18,000

- Wall-mounted configurations: $4,200-$9,600

Key Price Determinants:

✓ Boom length (add $600-$900 per extra meter)

✓ Rotation type (motorized adds $1,200-$2,500)

✓ Hoist specifications (chain vs wire rope)

✓ Control systems (pendant vs remote)

2. Detailed Cost Breakdown

A. Structural Components (35-45% of total cost)

- Steel frame fabrication

- Rotation mechanism

- Foundation requirements

B. Lifting Mechanism (25-30%)

- Chain hoist: $1,200-$2,800

- Wire rope hoist: $2,500-$4,200

- Specialized lifting attachments

C. Control Systems (15-20%)

- Basic pendant: $400-$800

- Radio remote: $1,000-$2,200

- Automated controls: $3,500+

3. Hidden Costs to Consider

- Installation: $800-$2,500

- Electrical work: $300-$1,200

- Permitting: $200-$1,000 (location dependent)

- Annual maintenance: $500-$2,800

4. Price Comparison by Type

| Feature | Economy | Mid-range | Premium |

|---|---|---|---|

| Price | $5,800-$7,200 | $8,000-$11,000 | $12,000+ |

| Rotation | Manual | Semi-motorized | Full motorized |

| Warranty | 1 year | 2-3 years | 5 years |

| Duty Cycle | Light | Medium | Continuous |

5. Regional Price Variations

- North America: +8-12% vs global average

- Europe: +5-10% (CE certification included)

- Asia: -15% (local manufacturing advantage)

- Middle East: +10-15% (desert-proofing)

Smart Buying Tips:

✔ Always request FOB and CIF quotes

✔ Verify compliance certifications

✔ Compare warranty terms carefully

✔ Ask for lifecycle cost projections

Current Market Trends:

- 5-8% annual price increase (steel costs)

- Growing demand for electric models (+12% YOY)

- Extended lead times (up to 12 weeks for custom orders)

For accurate 3 ton jib crane price quotes tailored to your specific needs, contact our engineering team with your:

- Required boom length

- Power specifications

- Usage environment details

- Desired features

Remember: The cheapest option often costs more long-term. Invest in proper capacity and quality for optimal ROI. Request our free Total Cost Calculator tool to compare options accurately.

Case Study: Automotive Assembly Line

Challenge:

A Tier 1 auto supplier needed to reduce forklift usage while handling 2.8-ton powertrain components across 8 workstations.

Dongqi Solution:

- Installed 3 mobile jib cranes with 5m booms

- Integrated anti-sway controls for precision positioning

Results:

📈 35% faster material transfer

💰 9-month ROI through forklift reduction

🔄 50% less product damage incidents

Why Global Clients Trust Dongqi?

🌍 Export Experience: 60+ countries served

📜 Certifications: CE, ISO, GOST, AS compliant

🔬 R&D Capability: 15+ patents in crane technology

🔄 Spare Parts: 10-year guaranteed availability

Get Your 3 Ton Jib Crane Today!

📞 Contact our engineers for:

- Free load calculations

- Custom configuration advice

- Instant quotation

📍 Visit our showroom to see operational demos