20-Mar-2025

Comprehensive Guide to Double-Beam Bridge Cranes: Cost, Price, and Technical Specifications

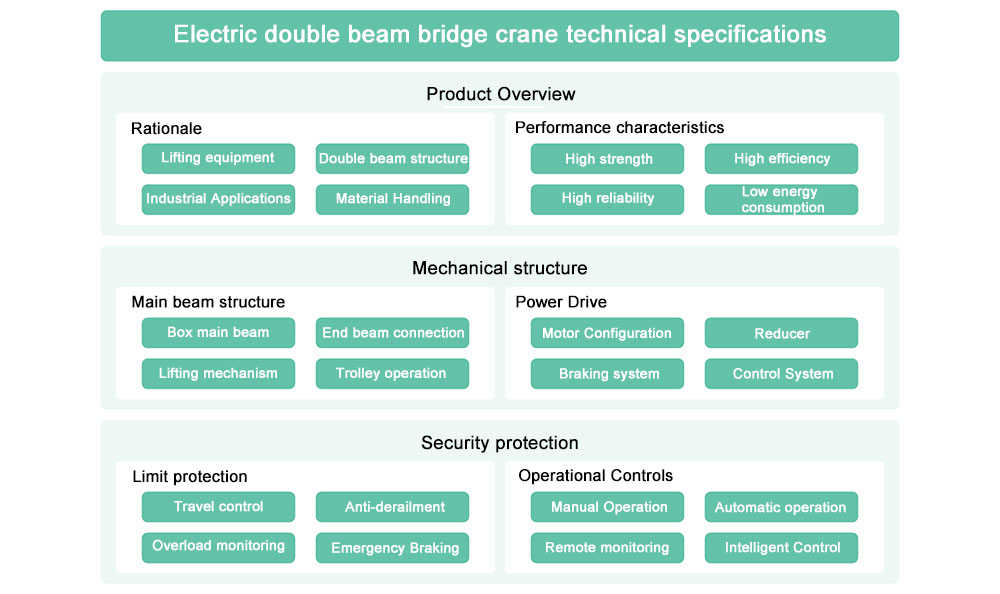

Double-beam bridge cranes are indispensable in modern industrial operations, offering high strength, efficiency, and safety. This guide provides a detailed analysis of double-beam bridge cranes, focusing on their technical specifications, cost, and price, to help Singaporean clients make informed decisions. Whether you are in manufacturing, logistics, or energy, understanding the features and benefits of double-beam bridge cranes will ensure you select the right equipment for your needs.

Product Overview

Introduction to Double-Beam Bridge Cranes

Double-beam bridge cranes are heavy-duty lifting equipment widely used in industrial settings for material handling, stacking, and transportation. Their double-beam structure provides exceptional load-bearing capacity and stability, making them suitable for complex working conditions. Powered by electric drive systems, these cranes offer precise control over lifting, trolley movement, and bridge travel, ensuring operational flexibility and reliability.

Application Scenarios

Double-beam bridge cranes are versatile and find applications in various industries, including:

- Manufacturing: For assembly line material handling.

- Logistics: For loading, unloading, and stacking goods in warehouses.

- Energy: For installation and maintenance of heavy equipment in power plants.

- Chemicals: For safe transportation of hazardous materials.

Advantages and Features

- High Load Capacity: The double-beam design ensures superior strength and stability.

- Precision Control: Advanced electrical systems enable accurate and efficient operations.

- Safety Features: Equipped with limit switches, overload protection, and anti-derailment devices.

- Customizable: Available in various models to suit different operational needs.

Cost and Price Considerations

Factors Affecting Double-Beam Bridge Crane Cost

The cost of a double-beam bridge crane depends on several factors:

- Load Capacity: Higher load capacities increase the price.

- Span and Lifting Height: Larger spans and greater lifting heights require more robust designs, impacting the cost.

- Customization: Additional features like automation or specialized safety systems can raise the price.

- Brand and Quality: Reputable brands with proven reliability may charge a premium.

Price Range

The price of double-beam bridge cranes varies based on specifications. For example:

- Standard Models: SGD 20,000–50,000 for basic configurations.

- High-Capacity Models: SGD 50,000–150,000 for heavy-duty applications.

- Customized Solutions: SGD 150,000+ for specialized requirements.

Cost-Saving Tips

- Evaluate Needs: Choose a model that meets your operational requirements without over-specifying.

- Compare Suppliers: Obtain quotes from multiple suppliers to find competitive pricing.

- Consider Long-Term Costs: Invest in energy-efficient models to reduce operational expenses.

Technical Specifications

Key Parameters

| Parameter | Description | Example Values |

|---|---|---|

| Carrying Capacity | Maximum weight the crane can safely lift | 5–500 tons |

| Span | Distance between the center lines of the main beams | 10–35 meters |

| Lifting Height | Maximum vertical reach of the crane | 6–30 meters |

| Work Level | Reflects the frequency and intensity of use | A1–A8 |

| Running Speed | Speed of crane movement in horizontal and vertical directions | 5–30 m/min |

| Acceleration | Rate of speed change during operation | 0.1–0.5 m/s² |

| Noise Level | Operational noise, impacting workplace comfort | ≤75 dB(A) |

| Energy Consumption | Power usage, affecting operational costs | 10–50 kWh/h |

Performance Comparison

| Model | Carrying Capacity | Span | Lifting Height | Work Level | Running Speed | Acceleration |

|---|---|---|---|---|---|---|

| Type A | High | Wide | High | A5 | Fast | Medium |

| Type B | Medium | Medium | Medium | A3 | Medium | Slow |

| Type C | Low | Narrow | Low | A1 | Slow | Fast |

Mechanical Structure and Design

Main Components

- Main Beam and End Beam: The box-type structure ensures high strength and rigidity.

- Hoisting Mechanism: Comprises motors, reducers, drums, and wire ropes for efficient lifting.

- Trolley and Bridge Travel Mechanisms: Enable horizontal and vertical movement with precision.

Power System

- Motors: AC, DC, or variable frequency motors for optimal performance.

- Reducers and Brakes: Ensure smooth operation and safety during emergencies.

Safety Features

Essential Safety Devices

- Limit Switches: Prevent over-travel and collisions.

- Overload Protection: Monitors load to avoid exceeding capacity.

- Anti-Derailment Devices: Ensure the crane stays on track during operation.

Additional Safety Accessories

- Emergency stop buttons.

- Sound and light alarms.

- Anemometers for wind speed monitoring.

Installation and Maintenance

Installation Process

- Site Preparation: Ensure the ground is level and tracks are properly aligned.

- Assembly: Follow manufacturer guidelines for assembling beams, mechanisms, and electrical systems.

- Testing: Conduct load tests and operational checks before commissioning.

Maintenance Tips

- Daily Checks: Inspect for wear, lubricate moving parts, and clean the crane.

- Regular Maintenance: Schedule periodic inspections to identify and address potential issues.

- Troubleshooting: Train operators to handle common faults like motor failures or brake issues.

Conclusion

Double-beam bridge cranes are a vital investment for industries requiring efficient and safe material handling. By understanding the technical specifications, cost factors, and safety features, Singaporean clients can make informed decisions tailored to their operational needs. Whether you prioritize cost-effectiveness or high-performance capabilities, double-beam bridge cranes offer a reliable solution for enhancing productivity and safety in your workplace.

Keywords

- Double-beam bridge crane

- Double-beam bridge crane cost

- Double-beam bridge crane price

- Double-beam bridge crane Singapore

- Industrial lifting equipment

- Heavy-duty crane solutions