9-Jun-2025

Top Running Crane Guide: Structure, Working Principle & Key Benefits

Introduction

A top running crane (also called a top-running overhead crane) is a heavy-duty lifting system designed for industrial applications requiring high load capacity and precision. Unlike underhung cranes, which hang from ceiling structures, top running cranes move on rails mounted on top of elevated runway beams, making them ideal for heavy loads (up to 500+ tons).

This guide explains:

✅ Top running vs. under running crane differences

✅ Core components & how they work

✅ Key advantages & industrial applications

1. Top Running vs. Under Running Crane: What’s the Difference?

Top running and under running (underhung) cranes serve different industrial needs. Here’s a quick comparison:

| Feature | Top Running Crane | Under Running Crane |

|---|---|---|

| Load Capacity | High (20–500+ tons) | Low (Up to 15 tons) |

| Installation | Rails on runway beams | Suspended from ceiling |

| Space Needed | Requires strong support structure | Works in low headroom |

| Best For | Heavy manufacturing, steel mills | Light-duty workshops |

Why choose a top running crane?

✔ Higher load capacity

✔ More stable for heavy-duty lifting

✔ Customizable for long spans

2. Core Components of a Top Running Crane

(Keywords: “top running crane parts,” “bridge crane components,” “overhead crane structure”)

A top running crane is a complex system with multiple critical components working together to ensure safe and efficient material handling. Below is a detailed breakdown of each major part:

A. Bridge Girder (Main Load-Bearing Structure)

(Keywords: “single girder vs double girder crane,” “top running crane beam design”)

The bridge girder is the primary horizontal beam that spans the work area and supports the trolley and hoist.

- Single Girder Design

- Uses one main beam with a trolley running on the bottom flange.

- Best for: Light to medium-duty applications (up to 20 tons).

- Advantages: Lower cost, easier installation, requires less headroom.

- Double Girder Design

- Features two parallel beams with the trolley running between them.

- Best for: Heavy-duty lifting (20–500+ tons).

- Advantages: Higher load capacity, better stability, longer lifespan.

Pro Tip: Double girder cranes are preferred in steel mills and heavy manufacturing due to their higher hook height and increased durability.

B. End Trucks (End Carriages – Movement System)

(Keywords: “crane end truck assembly,” “top running crane wheels”)

The end trucks are wheeled structures at each end of the bridge girder, allowing the crane to move along the runway rails.

- Key Components:

- Wheels: Typically made of forged steel or polyurethane for smooth rolling.

- Drive Motors: Provide motion (usually AC/DC electric motors).

- Brakes: Ensure safe stopping (disc or drum brakes).

- Buffers: Absorb shock at travel limits.

- Drive Configurations:

- Single Drive: One motor powers both end trucks (common in smaller cranes).

- Dual Drive: Separate motors for each end (better for heavy-duty, long-span cranes).

C. Hoist & Trolley (Lifting Mechanism)

(Keywords: “top running crane hoist types,” “electric wire rope hoist vs chain hoist”)

The hoist does the actual lifting, while the trolley moves it horizontally along the bridge.

| Hoist Type | Best For | Advantages |

|---|---|---|

| Electric Chain Hoist | Light loads (<10 tons) | Compact, low maintenance |

| Wire Rope Hoist | Heavy loads (10–500+ tons) | Higher lifting speed, durable |

| Magnetic Hoist | Steel plate handling | No slings needed |

- Trolley Design Variations:

- Standard Trolley: Manual or motorized movement.

- Geared Trolley: Uses motorized gears for precise positioning.

D. Runway System (Support & Guidance Structure)

(Keywords: “crane runway design,” “top running crane rail installation”)

The runway provides the track for the crane to move along the bay.

- Runway Beam Types:

- Structural Steel Beam: Most common, welded/bolted to building columns.

- Box Girder: Used for extra-heavy loads (e.g., in foundries).

- Rail Types:

- ASCE Rail: Standard for heavy-duty cranes.

- Flat Bar Rail: Used for lighter systems.

- Alignment & Maintenance Tips:

- Laser alignment ensures smooth operation.

- Regular lubrication prevents wear on wheels and rails.

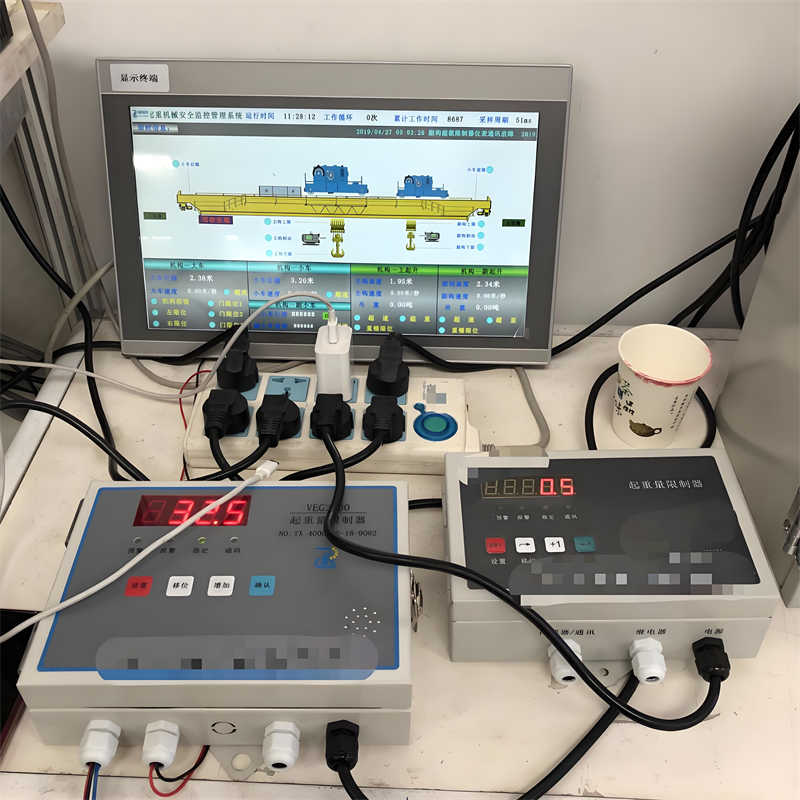

E. Electrical & Control Systems

(Keywords: “overhead crane controls,” “crane radio remote system”)

- Power Supply Options:

- Conductor Bars (Bus Bars): For large, high-duty-cycle cranes.

- Festoon Systems: Cable management for medium-duty cranes.

- Battery-Powered: Used in wireless remote-controlled cranes.

- Control Methods:

- Pendant Control: Wired handheld unit (economical).

- Radio Remote: Wireless operation (improves safety).

- Automated (AI/PLC): For smart factories (Industry 4.0).

Why Understanding These Components Matters

✔ Helps in selecting the right crane for your needs.

✔ Ensures proper maintenance to extend lifespan.

✔ Reduces downtime & repair costs.

Next Step: Learn how these components work together in [Section 3: How a Top Running Crane Operates].

3. How Does a Top Running Crane Work?

*(Keywords: *“top running crane operation”, “overhead crane working mechanism”, “how bridge cranes function”)

1. Basic Movement Axes of a Top Running Crane

*(Keywords: *“crane movement directions”, “XYZ-axis crane control”)

A top running crane operates along three primary axes for complete 3D material handling:

| Movement Axis | Component Responsible | Control Method | Typical Speed Range |

|---|---|---|---|

| X-Axis (Longitudinal) | End trucks along runway rails | Bridge drive motor | 20-200 ft/min |

| Y-Axis (Lateral) | Trolley across bridge girder | Trolley drive motor | 10-100 ft/min |

| Z-Axis (Vertical) | Hoist lifting mechanism | Hoist motor | 2-60 ft/min |

Key Feature: Modern cranes use variable frequency drives (VFDs) for smooth acceleration/deceleration, preventing load swing.

2. Power Transmission Systems

*(Keywords: *“crane power supply options”, “overhead crane electrification”)

A. Conductor Bar System (Most Common for Heavy Duty)

- How it Works:

- Insulated copper bars run parallel to runway

- Collector shoes on crane make sliding contact

- Advantages:

- Handles high currents (up to 1,600A)

- Low maintenance

- Suitable for dirty environments

B. Festoon/Cable Reel System

- Best for:

- Medium-duty applications

- Shorter runway lengths (<100ft)

- Components:

- Retractable cable tray

- Spring-driven or motorized reel

C. Battery-Powered (Emerging Trend)

- Applications:

- Outdoor use

- Explosive environments

- Smart factories with AGV integration

3. Control Systems & Operator Interfaces

*(Keywords: *“crane control methods”, “radio remote vs pendant control”)

Comparison of Control Options:

| Type | Operation Range | Best For | Safety Features |

|---|---|---|---|

| Pendant Control | Wired (10-30ft) | Basic operations | Emergency stop, overload cutoff |

| Radio Remote | Wireless (300ft+) | Complex maneuvers | Signal encryption, deadman switch |

| Cab Control | Operator cabin | Steel mills, high temps | 360° visibility, HVAC |

| Automated (AI) | Programmed paths | Repetitive tasks | Collision avoidance, IoT sensors |

Pro Tip: Modern radio remotes use 2.4GHz FHSS technology for interference-free operation in industrial environments.

4. Load Handling Mechanics

*(Keywords: *“crane load stability”, “anti-sway technology”)

Critical Safety Systems:

- Load Moment Indicator (LMI)

- Calculates safe working load in real-time

- Prevents overloading

- Anti-Sway Technology

- How it Works:

- Uses algorithms to predict swing

- Automatically adjusts speed

- Benefits:

- 50% faster positioning

- Eliminates manual correction

- Fail-Safe Brakes

- Dual-circuit electromagnetic brakes

- Spring-applied, power-released design

5. Operational Workflow Example

*(Keywords: *“crane lifting procedure”, “step-by-step crane operation”)

Scenario: Moving a 50-ton generator stator in a power plant

- Pre-Lift Checklist

- Verify runway clearance

- Inspect wire rope for defects

- Confirm load weight < crane capacity

- Positioning Phase

- Use X/Y axes to center hook over load

- Anti-sway system minimizes pendulum effect

- Lifting Sequence

- Initial lift: 6 inches (verify balance)

- Full lift at 10 ft/min

- Travel speed: 40 ft/min

- Placement Protocol

- Final positioning accuracy: ±1/4″

- Use micro-speed mode for delicate placement

6. Advanced Features in Modern Cranes

*(Keywords: *“smart crane technology”, “IoT in overhead cranes”)

Industry 4.0 Integration:

- Predictive Maintenance

- Vibration sensors detect bearing wear

- Thermal imaging for electrical faults

- Digital Twin Technology

- Virtual simulation of crane operations

- Optimizes movement paths

- Autonomous Operation

- RFID-tagged loads

- Automated storage/retrieval

Did You Know? The latest AI-powered cranes can reduce energy consumption by up to 30% through optimized acceleration profiles.

Why Understanding Operation Matters

✔ Improves safety through proper handling

✔ Maximizes efficiency in material flow

✔ Reduces downtime with preventive measures

4. Key Advantages of Top Running Cranes

✅ Higher load capacity – Handles extreme weights (up to 500+ tons).

✅ Greater durability – Built for heavy industrial use.

✅ Customizable spans – Adapts to wide facilities (e.g., shipyards).

✅ Precision control – Ideal for high-accuracy lifting.

5. Common Industrial Applications

Top running cranes are essential in industries like:

- Steel Mills – Handling molten metal and heavy coils.

- Power Plants – Installing turbines and generators.

- Shipbuilding – Moving large ship sections.

- Aerospace – Assembling aircraft components.

Conclusion: Is a Top Running Crane the Right Choice for Your Operation?

*(Keywords: *“top running crane selection guide”, “overhead crane buying factors”, “industrial crane ROI analysis”)

1. Decision Checklist: When to Choose a Top Running Crane

*(Keywords: *“top running crane vs alternatives”, “crane selection criteria”)

✔ Your Needs:

- Heavy loads (20+ tons) requiring stable lifting

- Long spans (30-150ft) between support columns

- High-duty cycles (100+ lifts/day)

- Precision handling (±1mm positioning)

✔ Your Facility:

- Existing runway beams or ability to install them

- Adequate headroom (minimum 2ft clearance above hook height)

- Robust building structure (can support crane + load weights)

✔ Your Budget:

- Higher upfront cost justified by 25-30 year lifespan

- Lower operating costs vs. mobile cranes for frequent use

When to Consider Alternatives:

- Under 15-ton loads → Underhung crane

- Temporary needs → Mobile gantry crane

- Outdoor, no infrastructure → Jib crane

2. Total Cost of Ownership Analysis

*(Keywords: *“crane lifecycle costs”, “overhead crane ROI calculation”)

| Cost Factor | Top Running Crane | Mobile Crane | Underhung Crane |

|---|---|---|---|

| Initial Purchase | $$$$ | $$ | $$$ |

| Installation | $$$ (requires runway) | $ | $$ |

| Operating Cost | $ (electric) | $$$ (diesel) | $ |

| Maintenance | $$ | $$$ | $ |

| Lifespan | 25-30 years | 10-15 years | 15-20 years |

Example ROI Calculation:

A $250,000 top running crane handling 50 lifts/day pays back in 2.3 years vs. $75/day mobile crane rental.

3. Future-Proofing Your Investment

*(Keywords: *“smart crane upgrades”, “automation-ready cranes”)

Ask Suppliers About:

- IoT readiness (sensor mounting points)

- Automation compatibility (PLC interfaces)

- Capacity headroom (can it handle future heavier loads?)

- Energy efficiency (regenerative braking options)

Emerging Technologies to Consider:

- Predictive maintenance sensors

- AI load optimization software

- Hybrid power systems (battery + conductor bar)

Final Recommendation

Choose a Top Running Crane If:

✓ You handle heavy loads daily

✓ Your facility has existing runway beams

✓ You need precision positioning

✓ Your operation justifies long-term investment

Consider Alternatives If:

✗ Your loads are under 15 tons

✗ You need temporary/mobile solutions

✗ Your building has low headroom