12-May-2025

Workshop Cranes

1. What is a Workshop Crane?

A workshop crane is a material handling device designed to lift, lower, and move heavy loads within industrial, automotive, and manufacturing workspaces. These cranes improve safety, efficiency, and productivity by reducing manual labor and minimizing workplace injuries.

Key Features of Workshop Cranes:

✔ Load Capacity – Ranges from 0.5 to 100+ tons, depending on the type.

✔ Mobility – Some are fixed, while others are mobile for flexible use.

✔ Operation – Manual (hand-powered), electric, or hydraulic.

✔ Structure – Freestanding, ceiling-mounted, or portable designs.

2. Types of Workshop Cranes & Their Applications

(1) Mobile Workshop Cranes (Portable Cranes)

Definition:

- Wheel-mounted cranes that can be easily moved around the workshop.

- Often feature adjustable booms for precise load positioning.

Applications:

✅ Automotive Repair – Lifting engines, transmissions, and heavy parts.

✅ Maintenance Workshops – Moving machinery for servicing.

✅ Small Factories – Flexible material handling in limited spaces.

Best Choice If:

✔ You need a crane that can be repositioned frequently.

✔ Your workshop has limited fixed lifting infrastructure.

(2) Overhead Workshop Cranes (Bridge Cranes)

Definition:

- Installed on ceiling-mounted runways, maximizing floor space.

- Includes single-girder (light-duty) and double-girder (heavy-duty) models.

Applications:

✅ Manufacturing Plants – Moving raw materials and finished products.

✅ Warehouses – Loading/unloading heavy pallets.

✅ Assembly Lines – Precise positioning of components.

Best Choice If:

✔ Your workshop has high ceilings and requires maximum floor space.

✔ You handle heavy, repetitive lifting tasks.

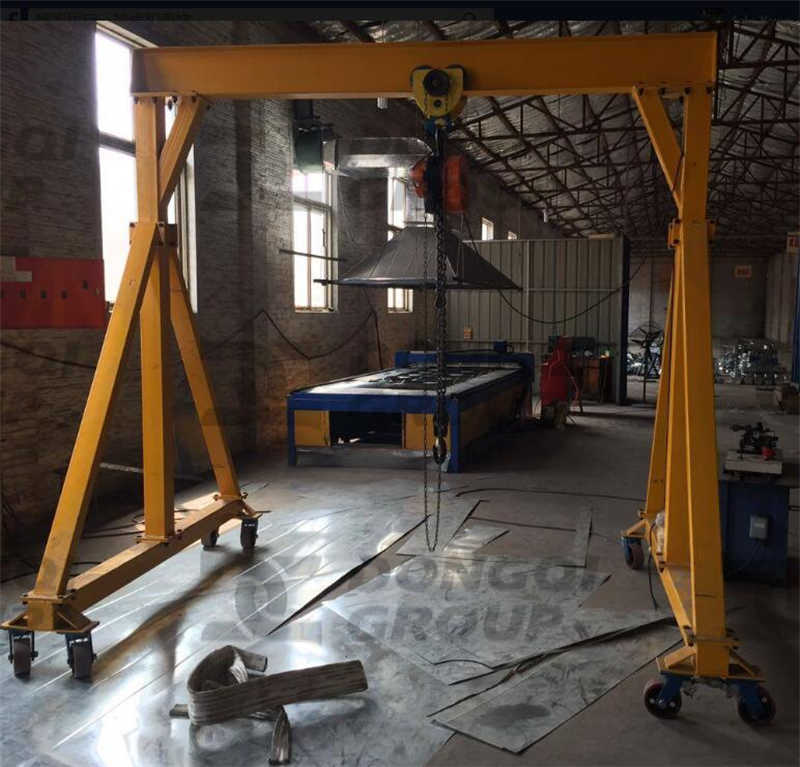

(3) Workshop Gantry Cranes (Freestanding Cranes)

Definition:

- Self-supporting structures that do not require ceiling mounting.

- Can be fixed or mobile (with wheels for relocation).

Applications:

✅ Shipyards & Construction Sites – Moving large steel beams and concrete blocks.

✅ Outdoor Workshops – Where overhead support is unavailable.

✅ Large Workstations – Handling bulky materials without obstructing floor space.

Best Choice If:

✔ Your workspace lacks ceiling support for an overhead crane.

✔ You need heavy lifting capacity (5-50+ tons).

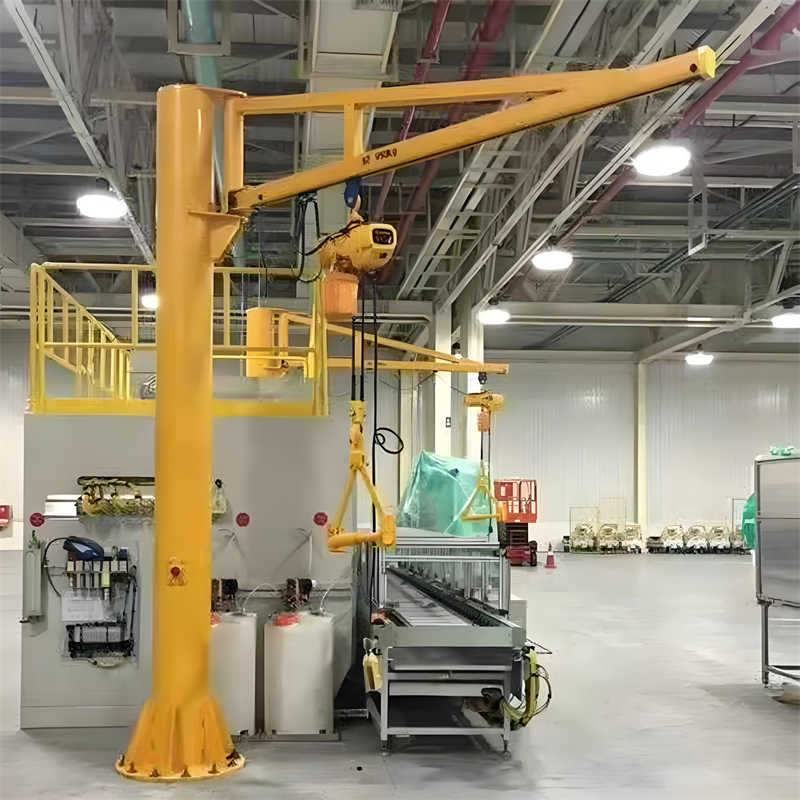

(4) Small Workshop Cranes (Jib Cranes & Mini Cranes)

Definition:

- Compact cranes designed for light-duty lifting in tight spaces.

- Includes wall-mounted jib cranes and free-standing mini cranes.

Applications:

✅ CNC Machining Centers – Loading/unloading workpieces.

✅ Auto Repair Bays – Lifting small engines or transmissions.

✅ Laboratories & Small Factories – Handling delicate or lightweight materials.

Best Choice If:

✔ Your workshop has limited space but requires frequent light lifting.

✔ You need a cost-effective, easy-to-install solution.

(5) Articulating Workshop Cranes (Flexible Arm Cranes)

Definition:

- Feature a rotating boom for precise load positioning.

- Often hydraulic or pneumatic-powered for smooth operation.

Applications:

✅ Aerospace & Automotive Assembly – Handling delicate or awkwardly shaped parts.

✅ Tight Workspaces – Where traditional cranes cannot reach.

✅ Cleanroom Environments – Pneumatic models for dust-free operations.

Best Choice If:

✔ You need high precision in load placement.

✔ Your workspace has obstacles or confined areas.

How to Choose the Right Workshop Crane

Selecting the ideal workshop crane requires careful consideration of multiple factors to ensure optimal performance, safety, and cost-effectiveness. Below is a detailed breakdown of key selection criteria:

1. Load Capacity Requirements

Determining Your Needs

- Calculate the maximum weight you need to lift regularly

- Consider future needs – allow for 20-30% additional capacity

- Account for load distribution – uneven loads may require higher capacity

Capacity Ranges by Crane Type

| Crane Type | Typical Capacity Range |

|---|---|

| Small Jib Cranes | 0.5-5 tons |

| Mobile Cranes | 1-10 tons |

| Single Girder Overhead | 1-20 tons |

| Double Girder Overhead | 20-100+ tons |

| Gantry Cranes | 5-50+ tons |

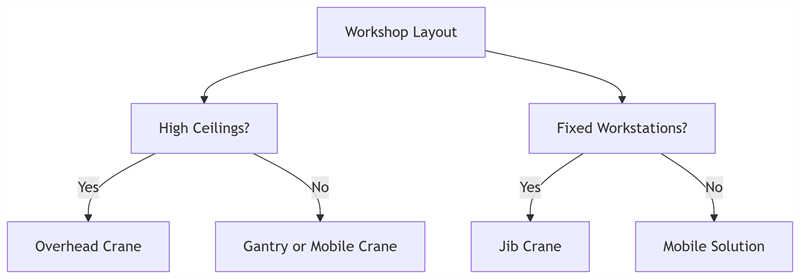

2. Workspace Assessment

Spatial Considerations

- Ceiling height: Overhead cranes require minimum clearance

- Floor space: Mobile/gantry cranes need operating room

- Obstructions: Columns, machinery, or doorways that limit movement

Layout Options

3. Mobility Needs Analysis

Fixed vs. Mobile Solutions

| Feature | Fixed Cranes | Mobile Cranes |

|---|---|---|

| Stability | Excellent | Good |

| Repositioning | Not possible | Easy |

| Installation | Permanent | Temporary |

| Cost | Higher initial | Lower initial |

When to Choose Mobile:

- Multiple workstations need service

- Temporary or seasonal lifting needs

- Limited budget for permanent installation

4. Power Source Selection

Comparison of Operation Types

| Type | Pros | Cons | Best For |

|---|---|---|---|

| Manual | Low cost, simple | Labor intensive | Occasional use <5 tons |

| Electric | Efficient, precise | Higher cost | Frequent use 5-50 tons |

| Hydraulic | Powerful, smooth | Maintenance | Heavy-duty 50+ tons |

| Pneumatic | Clean operation | Air supply needed | Sensitive environments |

5. Usage Frequency & Duty Cycle

Duty Class Recommendations

- Light Service (<10 lifts/hour): Manual or basic electric

- Moderate Service (10-20 lifts/hour): Heavy-duty electric

- Severe Service (>20 lifts/hour): Industrial-grade with premium components

Maintenance Considerations

- High-use cranes need:

- Regular lubrication systems

- Reinforced structural components

- Advanced control systems

6. Safety & Compliance

Essential Safety Features

- Overload protection systems

- Emergency stop mechanisms

- Anti-collision systems (for multiple cranes)

- CE/ASME compliance certifications

Operator Training Requirements

- Certification needs vary by:

- Load capacity

- Complexity of controls

- Work environment hazards

7. Cost Analysis

Total Cost of Ownership Factors

- Initial Purchase Price

- Installation Costs

- Foundation requirements

- Electrical work

- Structural reinforcements

- Operating Costs

- Energy consumption

- Maintenance parts/labor

- Expected Lifespan

- Typical 15-25 years for quality cranes

8. Customization Options

Common Workshop Customizations

- Specialized lifting attachments (magnets, grabs)

- Climate-resistant coatings

- Explosion-proof configurations

- Automated control systems

Selection Checklist

- [ ] Confirmed maximum load requirements

- [ ] Measured available workspace dimensions

- [ ] Determined necessary mobility features

- [ ] Selected appropriate power system

- [ ] Verified compliance with local regulations

- [ ] Compared total cost of ownership

- [ ] Identified necessary customizations

Need Professional Guidance?

Dongqi Crane engineers provide free workspace evaluations and customized recommendations to ensure you select the perfect workshop crane solution. Contact us today for a no-obligation consultation.

4. Why Choose Dongqi Workshop Cranes?

✔ Custom Solutions – Tailored to your workshop’s size and lifting needs.

✔ High Durability – Made from premium-grade steel for long-term use.

✔ Global Supplier – Trusted in Australia, Europe, North America, and beyond.

✔ Competitive Pricing – Cost-effective without compromising quality.

Need a Workshop Crane?

📞 Contact Dongqi Crane today for expert advice and a free quote!